SCAT 77 Series Big Block Post Small Block Chevy Forged Crankshaft

SCAT Crankshafts has a new player in the family. The new 77 Series Big Block Post, Small Block Chevy 4340 Forged crankshaft is ideal for Blower, or Dry-sump pulley applications.

Behind the Scenes Look at Scat Crankshaft Manufacturing

With over 50 years of manufacturing experience, SCAT Crankshafts proudly produces some of the finest crankshafts in the world. With thousands of race proven wins, SCAT ensures customers receive the highest quality components on the market. In addition, SCAT rods are made from a two-piece chromoly steel forging to ensure maximum strength and durability for small and big block Chevy, Ford, Chrysler, Pontiac, Honda and many more. Visit SCAT at PRI in booth #2125.

Internal Affairs – Diesel Crankshafts and Rods

Despite having similar appearances, a diesel crankshaft has some primary differences from its gasoline counterparts. A gasoline engine uses a spark to ignite the fuel. A diesel engine, operating at a much higher compression ratio, uses the heat produced by compression to ignite the fuel. Diesel engines typically have a longer stroke than the bore diameter, so to handle this load, diesel crankshafts are much larger physically.

K1 Crankshafts and Connecting Rods for GM LS Engines

Forged from 4340, the tough, shock and impact resistant alloy steel, K1 Technologies has introduced a new range of high-performance crankshafts and H-beam connecting rods for racing and high performance LS engines.

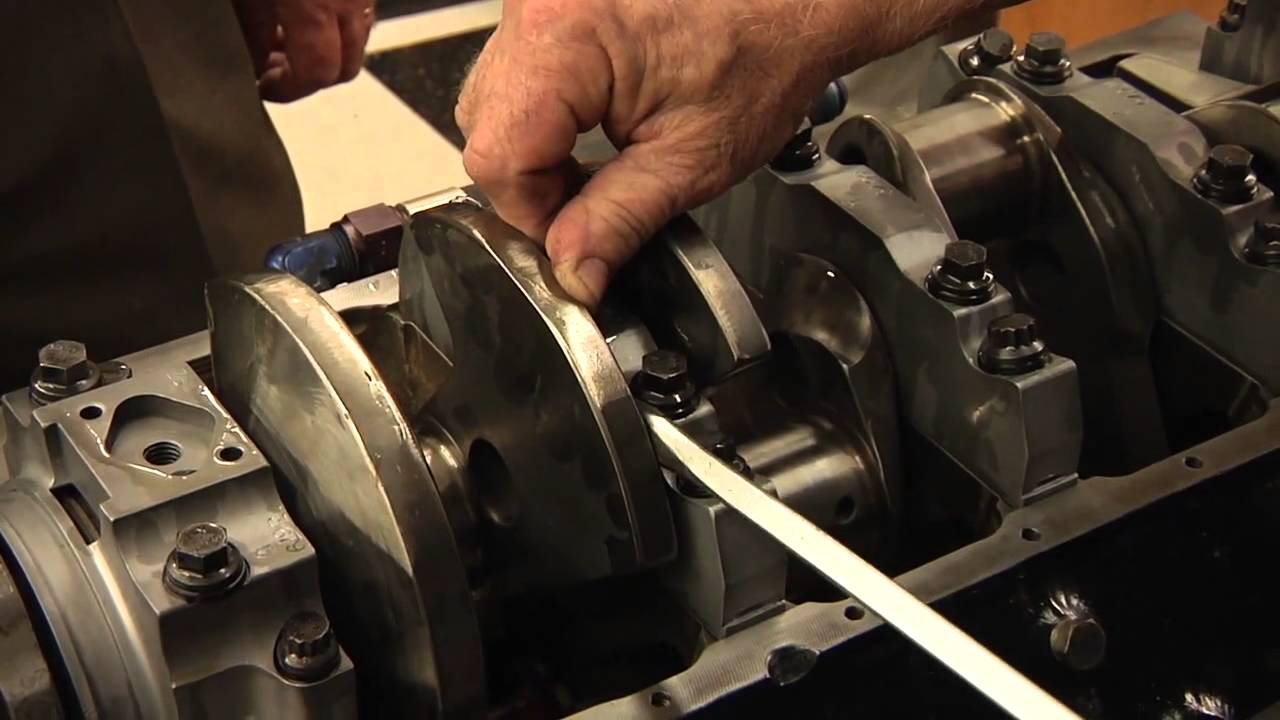

Replacing Crankshafts, Connecting Rods and Bearings

The crankshaft, connecting rods and bearings are extremely important in every engine build, whether mild or wild, because they convert the reciprocating motion of the pistons into rotational torque. The longer the stroke, the greater the leverage effect and the greater the torque output of the engine. There are three things that need to be

Scat Chevy Crankshaft

Scat offers a new 9000 Cast GMC diesel crankshaft available for the Chevy 6.5L engines. For stock replacement or mild performance use, why risk running an old factory crankshaft? Scat offers builders a new, stronger replacement. Features include: precision-ground, straight-shot oil holes and rough balanced — all at a great low cost. p/n: 9-6.5L-3819-6280 Short No. 965L3819. Stroke:

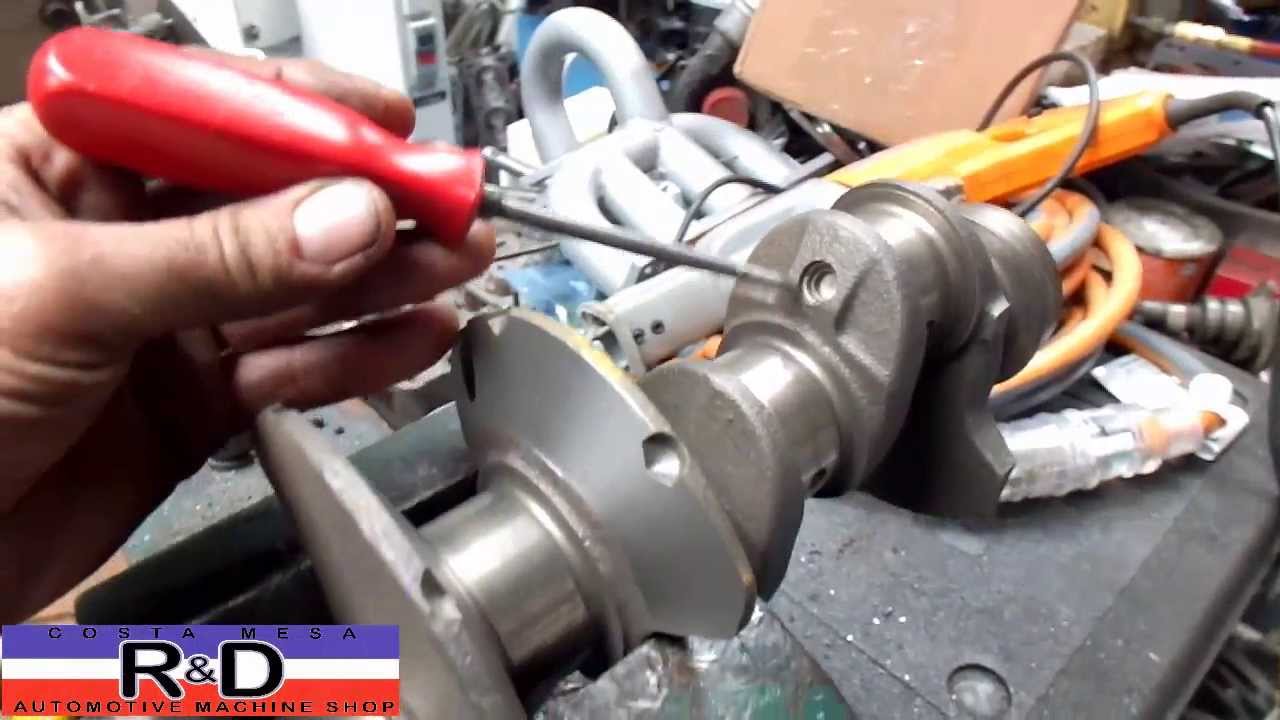

Cleaning Out Crankshaft Sludge Traps

The importance of properly cleaning out the sludge traps in a crankshaft goes without saying. John Edwards at Costa Mesa R&D Automotive Machine Shop explains how its done on a Fiat crankshaft.

Crankshafts and Bearings for Street Performance and Racing

The crankshaft and bearings are the foundation of any engine. The type of bearing and crankshaft materials that are used, their strength properties, fatigue resistance and ability to handle high torque loads ultimately determine how durable the engine is and whether it goes the distance or self-destructs. Most engine builders have strong opinions and

Lunati Voodoo Crankshafts

The backbone of your engine and the foundation of your bottom end is the crankshaft. Voodoo Crankshafts from Lunati are engineered from 4340 non-twist forged steel that is known for its durability and strength in high-performance applications. All Voodoo Cranks are nitride heat treated with micro-polished journals to add even more durability. Lightening holes in the rod

Audi 2.8L V6 Rear Crankshaft Seal Leaks After Replacement

This condition affects 1996 A4 with 2.8L V6 (Engine Code AFC). When replacing the seal, the new seal is supplied pre-installed in the flange. Seal/Flange P/N: 078 103 171H Flange gasket P/N: 078 103 181 (must be ordered separately). Caution: Part numbers are for reference only. 1) Carefully remove installation tool that comes with seal

Custom Crankshafts and Connecting Rods

As an engine builder, you get to decide what parts go into the engines you build. If you’re rebuilding a stock engine to stock specifications, you’re probably going to use a reconditioned stock crankshaft and connecting rods to keep costs down. There’s no reason to upgrade these parts because they should be adequate for the

Ford 2.3/2.0L Duratec Requires Special Tools To Service Crankshaft Pulley

These engines, (excluding 2.0L SPi and Zetec engines) may experience damage if the crankshaft pulley bolt is loosened during service without first installing the following Special Service Tools. The crankshaft pulley bolt also retains the crankshaft cam drive sprocket which is NOT keyed to the crankshaft, so valve timing mayshift if the crankshaft pulley bolt

Removing Crankshaft Pilot Bearings (#3)

Soak the paper in water and stuff it into the hole, and then drive it in with a bolt or other tight fitting tool. Keep cramming in more wet toilet paper until the bearing pops out. In my experience, this method is much quicker than using bearing removal tools and is way cleaner than

Removing Crankshaft Pilot Bearings Revisited (#4)

When removing a crankshaft pilot bearing, the easiest way is to use modeling clay or Play-Doh. Pack the clay into the hole first by hand, and then hammer it in with a tight fitting bolt or blunt chisel. It doesn’t take much force to make the bearing pop out. There is no mess, and the

Debunking the 10 X 10 Crankshaft Myth for Customers (#5)

First of all, in normal use or even high performance use, a used crankshaft will not “clean up” to standard specifications and will usually have to be ground to .010? undersize. The crankshaft has then remained 98+ percent as strong as new. The problem arises when “spinning” or “hammering” (knocking) a bearing. The crank will

Understanding Differences, Challenges Between Crankshaft Position Sensors

I don’t believe that I have ever written about watching out fordamaged as-cast reluctor rings, spark triggers or whatever other namesome manufacturer has given them to create their ownidentity/ownership. It’s not as bad as the variable displacementacronyms but still running a close second. ANYWAY. Before we talk about this issue you need to understand

Sheared Crankshaft Sprocket Keys Found on Some GM 6.2L Diesel Engines

A new hardened washer, p/n 23504011, is availalbe for improved clampload of the crankshaft sprocket to the crankshaft by the crankshaftbolt. Installation torques for the hardened washer have been increasedto 177 to 185 ft.lbs. (240 N.m /250 N.m). Parts are currently available from GM and other suppliers should damperloosening occur, resulting in the crankshaft sprocket

Rear Crankshaft Oil Leaks on 2005-2007 GM Atlas 4.2L Engines

Verify the leak by looking at the end of the crankshaft (Figure 1). If oil is present in the bore (where the torque converter nose engages the crankshaft), a specialservice procedure should be performed. If the bore is dry, or oil appears to befrom the seal area, perform normal oil leak analysis. A service cup