When base oils featuring both low viscosity and high volatility are used to make low viscosity motor oils, the higher volatility results in higher oil consumption.

A recent Consumer Reports article highlighted the increasing trend of new vehicles that “use” a fair amount of oil, as much as one quart for every 1,200 miles.

This problem is particularly apparent in lightweight “OW-” oils often found in performance engines. The reasons for this consumption are not mechanical, such as stuck rings or loose clearances. The reason for this “vanishing oil” is due to a technical term that also starts with a “v”— volatility.

Just like water begins to evaporate before it boils, motor oil will also evaporate inside your engine. When motor oil splashes up to cool the underside of your piston, the 500°F piston temperature causes the oil to evaporate.

According to Driven Racing Oil, not all oils evaporate at the same rate. Typically, motor oils featuring lighter base oils evaporate more quickly at high oil temperatures. Think of pouring gasoline and diesel oil on the ground. Which one evaporates first? The gasoline does because gasoline is lighter than diesel, and so it has a higher volatility.

The scientific test for evaporation tendency is called NOACK Volatility. Some low viscosity base oils will evaporate at a rate as high as 49%. When base oils featuring both low viscosity and high volatility are used to make low viscosity motor oils, the higher volatility results in higher oil consumption.

Obviously, more oil is consumed as more of it evaporates. In high temperature areas, such as on the underside of the piston and in the piston ring zone, higher volatility oils evaporate rapidly. These oil vapors can cause deposits on intake tract runners and valves as the oil vapors travel through the PCV system and out the exhaust system.

Many high performance engines now feature PCV oil separator catch cans in order to catch the oil vapors and prevent these deposits.

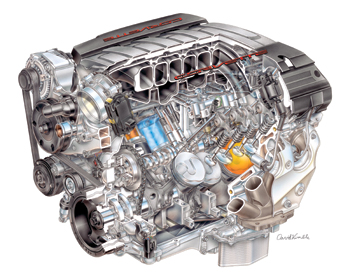

In fact, the new 2014 Corvette LT1 engine features integrated PCV oil separators. As engines begin to incorporate direct injection, keeping oil out of the PCV system is critical. With direct injection no fuel is available to clean the intake valves, so it is critical to limit the oil vapor.

Advanced synthetic base oils limit volatility, and that reduces oil consumption. The current API SN volatility limit is a maximum of 15%. In comparison, advanced Poly AlphaOlefin (PAO)-based motor oils can have as low as 5% volatility.

Driven Racing Oil said it features mPAO, a next-generation synthetic base oil in all of its performance lubricants, allowing the company to create lightweight motor oils that retain a high HTHS (High Temperature High Shear) viscosity, making them less sensitive to heat and less prone to the evaporation problems outlined above.

For more information on mPAO technology, visit www.drivenracingoil.com.