What to Consider When Contemplating Power Adders

If it wasn’t big-inch, high-horse, ground-pounding Detroit muscle, it just didn’t matter to me. It was the middle of the ‘80s, and I thought I knew it all. Sure, I got Car & Driver, and I was getting used to hearing terms like turbocharger all the time, but I still wasn’t reading about them in Muscle Car Review, so they probably didn’t matter.

I read about the new Buick Regal and its turbocharged V6. I thought, so what? I’m also reading about turbo lag, and that just sounds slow. After all, it’s not a 1970 GSX Stage 1 car, and it’s only a V6. This thing doesn’t deserve to roll through the rubber tracks put down by real muscle.

Then I got to drive one. “I’ll prove how wimpy this thing is,” I thought. I was cautious, and it wasn’t my car, so I gave it just a little throttle at first. Nothing. I gave it some more. Nothing. Knowing I had proven my point, I gave it my all. Before I knew it I was sideways. Okay, I like this car.

It turns out the quarter-mile times were right for that G-body Buick. I didn’t know anything about turbochargers, or any power adders for that matter. I expected mountains of torque from something that ran a respectable quarter-mile. And I thought that turbo lag meant the turbo was causing a problem. I was wrong about that too. The V6 ran just as it should. It’s just that as soon as the turbo opened up a can of you-know-what, it ran a whole lot better!

What’s changed since then? Quite a bit, and the best part is we’ve figured out how to utilize all the common power adders – turbochargers, superchargers and nitrous – to an efficient extent. We also know all too well the strain they put on engines and how we need to build one for it to hold together when we unleash the unnatural aspiration we so often desire.

The “big three” power adders are king of the hill when you’re looking for big-time results, but another player that is often the first step for someone and generally accompanies one of the big three is a tune, chip tune or performance tuner. There’s been plenty of speculation as to their ultimate benefit, but the fact is they can offer an increase in performance and in some cases fuel economy.

“Putting the tune on it” used to be the job of a skilled technician with a thorough understanding of fuel and ignition principles. Their eyes, ears and nose were the only tools needed outside of a dwell meter, timing light and a screwdriver. Designing a modern-day tune requires the same knowledge, but with an in-depth understanding of computer programming. Gone are the days of manual adjustments. This is all done from a desk.

No disrespect towards the modern-day tune, but it is a fact that while they will improve performance, their claims of power are not always met in a stand-alone state. In other words, you won’t get the most out of one of these until you’re ready to bolt on the real hardware.

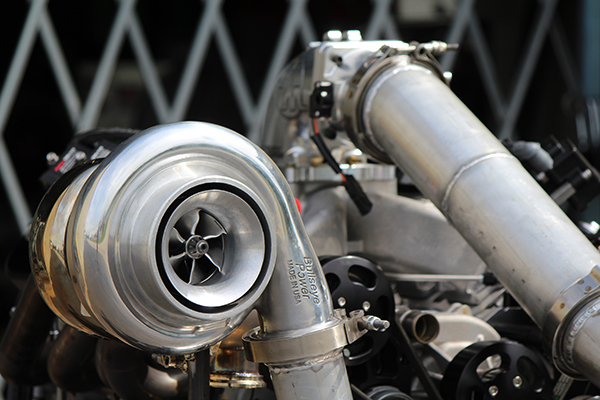

Turbos vs. Superchargers

It’s hard to call if there will ever be a winner, but there will always be a difference in opinion. Both are a means of forced induction.

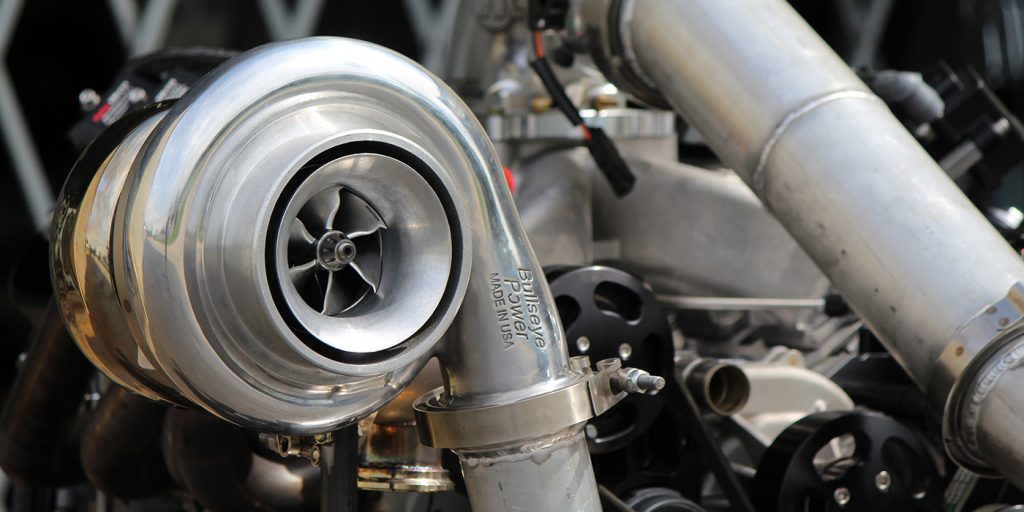

Turbochargers will always be known for providing “free power,” since they use the flow of exhaust to spin the turbo and build pressure in the intake. An advantage of turbos is the ability to produce power over a broader range of torque.

Now as I eluded to early on, does lag really exist? In concept, yes, if you’re waiting for the turbo to do what it does. But until then, the engine runs as it runs. If the turbo is on a small displacement engine with relatively low torque, you’re just going to have to wait. On the other hand, if you’ve turbocharged a stump-puller, it already feels pretty good when you hit the gas.

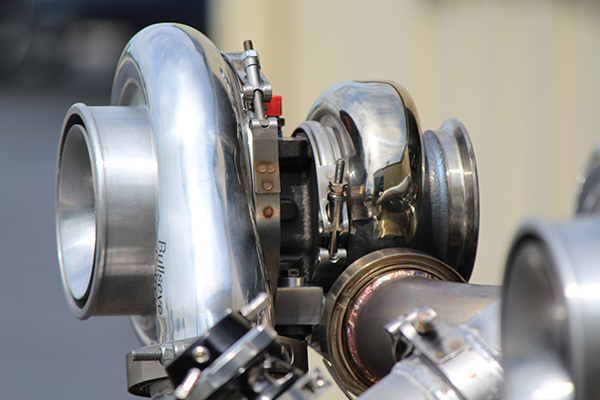

A “double bonus” is a variable twin-turbo setup, which has become especially popular on diesel engines due to their low-rpm operation. A variable twin-turbo setup consists of two turbochargers, a small one and a large one.

At low rpm, an engine does not have a lot of exhaust flow, so all of the exhaust is directed through the smaller turbo. The low exhaust flow picks up velocity passing through the smaller turbo, spinning it up for low end boost.

In the mid-rpm range, the exhaust is partially diverted to the larger turbo, which begins to spool up and pre-compresses the intake charge, which is then compressed further once it reaches the small turbo.

At high rpm, the exhaust is directed through the large turbo, which then provides all the boost for the engine.

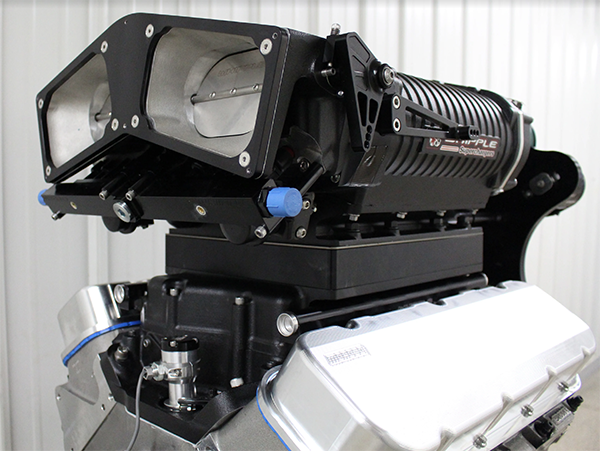

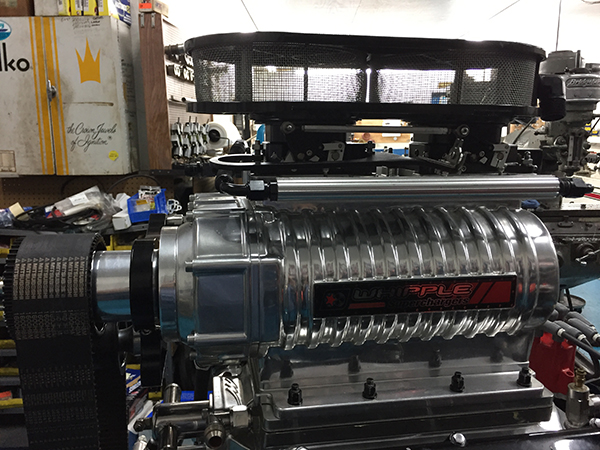

Now, the argument for a supercharger is they are overall less expensive and less complicated to install, and they provide instant throttle response. Superchargers are belt-driven, so they consume engine power to operate, but you’ll get a lot more than you give up.

Supercharger drive pulleys can be easily changed for additional boost, but the ultimate speed of a supercharger is limited to the speed of the engine, whereas a turbo does not have this restriction. There are different types of superchargers, the roots, screw and centrifugal styles. Primary differences include clearance, power range and ease of installation.

There’s a lot to consider when deciding between a turbo or supercharger and your customers are going to look to you for an answer. Superchargers give you instant response, are less expensive, known for their dependability, and they also look really cool. Clearance can be an issue though, so just as building an engine, you’ll have a lot of questions to ask.

Turbochargers are more efficient with no parasitic power loss, offer great high rpm power and are generally much quieter than a supercharger. Turbos can be a little more difficult to tune, but it’s nothing that a little patience can’t take care of.

Whichever way you decide to go, you’re packing in the horsepower. Did I forget about the last of the big three? — No. But I’ll leave the topic for another day. In the meantime, I’ll just keep reading my magazines about big cubes and big horse. Maybe I should get one of those bumper stickers “All Throttle and No Bottle.” Or maybe I’m just afraid of what the bottle will do — my turbo experience was good enough. EB