Clint Eastwood is well-known for his quintessential ‘spaghetti western’ personas. His characters typically offer up a mean scowl while biting half a cigar. That’s exactly the look Doug Rogers was going for with his PistonFace artwork. Rather than letting pistons get thrown in the trash or melted down, Doug, under his PistonFace moniker, retains the history of these pistons and makes them into pieces of art that emote and tell a story.

“I’ve developed a signature look,” Rogers says. “The first face I did had kind of a scowl, bite and chomping down on a cigar, which was basically due to Clint Eastwood. I was a big Clint Eastwood fan and I just remember the drifter character from the spaghetti westerns. He always had half a cigar and was always biting down on it with a scowl. He’s kind of mean-looking and that’s what I wanted to do, and it goes with my slogan – ‘giving old pistons new attitude.’”

In the world of engine rebuilding, we’re inherently giving old engines new attitude and a second chance at life, but in more cases than not, many engines and parts become forgotten trash. However, there are a number of people who have gotten creative with old engine components to turn them into something else, and Doug Rogers of PistonFace in Salem, OR, is a great example of how you can rescue little pieces of engine history one piston at a time.

It’s his passion for art and history that we want to shine a spotlight on. Due to that passion and creativity, Doug can no longer walk passed a piece of metal without seeing something that could be done with it.

“What’s weird is I can’t walk past metal now and not see something,” Rogers says. “Before, I would have scrapped things or threw things away. Now, I realize I can use that for something, so it’s made me a bit of a hoarder.”

Doug’s love for all things automotive didn’t simply start with his PistonFace artwork (pistonfaceart.com). He’s been around car culture his whole life and has spent his entire career in it.

“For me, it all started with the movie American Graffiti, I guess,” he says. “We had American Graffiti cruise nights in El Cajon, CA. As a kid, I had all these images of fast cars. In the neighborhood there was always these fast cars and hot rods and stuff.

“I graduated high school in ‘84 and I got a job at a gas station. All my money went into building cars. We used to illegal drag race and all that stuff. Second Street was a big deal in El Cajon – it always made Hot Rod magazine’s top cruise spots. That car culture was all around there.

“In 1992, I had worked at the gas station for eight years and that was kind of winding down and they were changing direction. I was 25 or 26 and I didn’t know what I wanted to do with my life. My parents lived up in Salem, OR, and there is a community college nearby called Chemeketa Community College, which had an automotive program. I already had about $30,000 in tools – I’d been buying Snap-on since I was 18 – so I decided to go into the automotive program.”

Doug graduated in 1994 and got a job working as a technician in a GM dealership. Fast forward to 2018 – he had been working 24 years straight with GM dealerships as a service technician doing drivability and electrical.

“At that time, I got an opportunity to go back to Chemeketa Community College and work as an automotive instructor,” he says. “That’s what I do now.”

Part of accepting the automotive instructor position meant Doug had to take a sizable pay cut, and his brother-in-law, who is a teacher in California, suggested Doug find something he loved to do and make some money on the side.

“When I was still working as a tech, I had a jet ski piston that I scratched a face on with a cordless Dremel,” he says. “I drilled some holes for eyes and a nose. I took it to work and showed my friends who thought it was really cool and they asked if I could make them one. Of course, I said OK. We found a junk piston around the shop and I carved somebody up one. The next thing you know, I put the photos of it on Facebook and everybody started asking if I sold those.”

Doug had found his side gig, although he admits, his early piston faces were fairly rudimentary. He still has his very first one in his office, which he made in November 2017.

“My friend talked me into getting on Instagram and that’s where it just took off,” Rogers says. “It motivated me. I’ve met other artists through the internet who I’ve collaborated with and I’ve made some good friends around the world even though we haven’t met in person. It’s just awesome. I now have 8,500 followers who appreciate what I do. It’s just been a blessing. It’s kind of a therapy.”

Looking at Doug’s piston art, you might guess he has a fairly extensive art background, but it seems his talents came naturally and have been honed over the years.

“I’ve always had a little bit of an artsy side, but I’ve never considered myself to have a talent really,” he says. “I don’t know where my ability comes from other than I just like things that look neat. I’m not the first person ever to carve a piston, or the last to do it, but I just developed a style that I like. I like them to emote. I like them to have an attitude. That’s just my personality. I’m kind of a jokester and I like custom culture art like Ed Roth (Rat Fink) and stuff like that. I don’t know where it came from, but it’s evolving and I’m going with it.”

How does Doug make his works of piston art? He primarily carves them using hand tools and a lot of creativity.

“I just have small tools here,” he says. “I don’t have a lathe or any machines. I do this with Dremels, hand bits and hand drills. Right now, I have a Craftsman. My tools are just mechanic’s tools – thread inserts, angled side cutters, various hand drills, files, micro files, brass hammers, miniature ball peen hammers, and crescent wrenches.

“I have tons of drill bit sets with different coatings. I have an 8˝ drill press for my bench that I do some stuff. For the most part, when I drill a piston out, I have a DeWalt cordless drill that I use because they have a little clutch on them. I just hold it by hand with a box to catch the chips.”

The pistons themselves come to Doug in a number of ways. He either purchases them himself, customers send him their old or damaged pistons to work on, or piston manufacturers donate the pistons they can’t use.

“I’ve been fortunate enough that I reached out to JE and CP Carrillo, etc. after somebody suggested that I do that,” Rogers says. “CP and JE have been awesome by sending me some scrap. I can’t think those guys enough. Those people have been so gracious and nice, and I tag them on social media. When I use one of their pistons, I try and identify what it’s from. With CP, I’ve got some really cool, custom, one-off pistons.

“I prefer it if somebody sends me a piston that they have a cool story with. My whole thought with this is that all these pistons have a story. If they could talk, they could tell you some sketchy or harrowing tales of what happened. We’ve all had close calls or we’ve all over revved engines and some of these come with some real awesome, natural damage.

“A guy sent me a ‘55 Harley Panhead where his throttle plate screws came out. I did what I do to the piston and then I was able to leave the damage there. I also just did a 352 Ford piston for a guy who has a killer old Ford wagon and the piston has all kinds of detonation damage on the top and it just looks really cool, so I retained the damage. That piston was probably going to be melted down and thrown in the trash. Now it’s a story and it’s tied to him.”

You might also notice that many of Doug’s pistons feature a bullet cigar to complete the look or add to the piston’s story. Doug saves those old bullet casings specifically for his art.

“Using shell casings are kind of my thing,” he says. “One of my hobbies was shooting and reloading ammunition. I keep those spent casings. If you go out to a shooting range or into the woods where people have been shooting for sport, you’ll find brass all over the ground. That’s more trash that could be reused.

“I use a .45 ACP in a lot of my pistons because the size is good and that’s an iconic round from the Browning 1911 pistol, which is an iconic pistol from the United States. John Browning is the grandfather of the machine gun. To fit the cigars, I’ll buy toothpicks and mix up J-B weld and some epoxy to hand fit the cigars and press fit them in there. I like the historical nature of all of this and I’m happy doing what I’m doing, so I think that translates.”

When it comes to the piston’s overall design, Doug clearly has his style, and a majority of customers send him a piston and allow him to do his thing. However, a small majority will ask him to create something more personal or specific.

“I’m trying to do things that I like to do,” he says. “However, people always ask me, ‘Can you do this or that on a piston?’ I don’t want to be a pre-Madonna or anything, and I don’t always have the skill to do what they want, but I like when people just say, ‘Do what you do.’ That’s my favorite.

“When people ask me to do something, sometimes it’s out of my wheelhouse or it’s just so labor intensive, so it becomes a challenge. A lot of times those pistons just don’t work. The things that come out best are the things that are out of the artist’s mind.”

Doug’s biggest motivation with his piston art is seeing the reaction of the customer. They often tag him in photos to show him what they’ve done with the piston or where it ended up. Over the years, Doug has done hundreds of pistons from your everyday Fords, Chevys and Cummins to Bentleys, Talbot Lagos, Flatheads, Yamahas, Hondas, and Harleys too.

“I didn’t even start numbering them until about 100, because I finally realized this was going somewhere,” Rogers says. “I’m just creeping up on 300 pistons.”

While some piston faces come together quicker than others, Doug’s work is certainly labor intensive, and the occasional mistake still happens. Doug just rolls with it.

“I don’t weld on them or do anything to change the piston too drastically,” he says. “When somebody sees it, I want there to be no doubt that’s a piston. When you start doing too much to them, they kind of lose their original feel. I want it to be immediately recognized as a piston. If I make a mistake or the Dremel bit grabs and dances across the front, I’ll try and either sand it out or create damage to incorporate it into the piece. I just Bob Ross that stuff – happy little accidents. I don’t have the afro, but I do have the attitude.

“I used to get so bummed out and upset when I made a mistake. When somebody sends you a piston, that’s a lot of pressure because that’s their history they’re sending you. I find great joy in creating the pistons I make, and in the joy they bring others. I believe every piston heading to the scrap heap has a story to tell. I try to leave behind imperfections or damage when possible to help preserve the history of the piece because when their stories are passed down, my artwork helps keep those stories alive.”

Make sure you check out all of Doug’s PistonFace art at pistonfaceart.com, on Facebook @pistonface, or on Instagram @pistonface. EB

Other Uses for Engine Parts

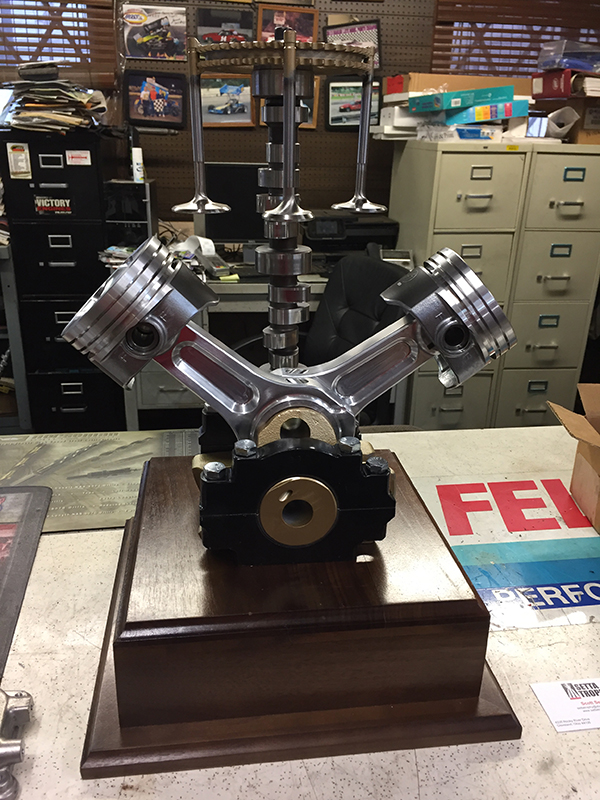

It doesn’t take too much searching to find plenty of people with similar creativity as Doug Rogers has. Many folks are using old engine/car parts for unique things. Take our pal Ray Banyas at Victory Engines in Cleveland, OH for instance.

Ray has been making trophies out of old engine parts for years. From simple connecting rod and piston trophies to elaborate ones with camshafts, timing gears and valves to trophies that even rotate using battery-powered motors and have spark plugs that actually fire!

“What sparked me making trophies using engine parts was John Brubaker of Federal Mogul,” Banyas says. “Years ago, he came into the shop needing a unique piece. I use parts that are left over from old builds or new parts without a home. It got to be like a challenge – how trick can I make this thing?”

Beyond using engine components for art, many people have created pieces with more function such as furniture – tables, chairs and couches – using connecting rods, blocks, axles, and springs. Others have repurposed parts for unique areas of the car itself that they weren’t originally intended for, such as piston radiator caps or shift knobs, or connecting rods as exhaust hangers. The creativity is only limited by a person’s imagination.

What would you create with old engine/car parts? Tag us in your creations and we’ll share the best ones!