I was recently contacted by a friend from North Carolina wanting to send me a Honda dirt bike cylinder for resizing. When I asked why he wanted to send it here to Pennsylvania for the work, his answer was that he couldn’t find anyone local to do the job. This was a surprise to me because that region is host to more engine specific businesses than any other part of the country. That led me to take stock of how much mail-in work we have gained in recent years.

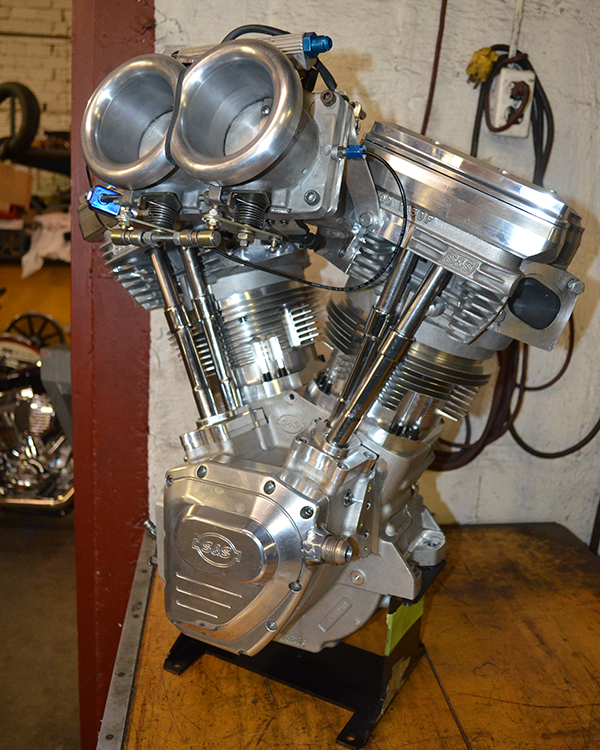

Here at GMS Racing Engines, we specialize in Harley-Davidson-based V-Twin engines for performance and racing use. However, it wasn’t always that way. Before GMS became all V-Twin roughly 12 years ago, we were a full-service auto machine shop doing everything from general auto shop support (press work, flywheel grinding, welding, valve jobs, general engine work) to full-blown racing engines for many different types of competition. I still did a good deal of motorcycle engine work in the background, fueled mostly by my interest and success in racing Harleys. About that same time, the whole automotive industry changed in ways that affected small auto machine shops.

In years past, automotive and motorcycle engines required major service during their lifetimes to perform long enough to wear out the rest of the vehicle. This was the bread and butter of the small auto machine shop. All of the service work I mentioned earlier was steady and plentiful keeping nine or 10 shops busy in the region around Uniontown, PA where GMS is located. Cleaner burning fuel, advancements in motor oil, higher operating temperatures, and general advancements in engine technology have given us modern engine life three to five times greater than before. A modern automotive engine, and its motorcycle counterpart, can perform throughout the entire life of the rest of the vehicle without major service if properly used and maintained.

Now, there are exceptions to this trend, but by and large the work needed to keep a shop of any size busy has changed dramatically. In my area, there is only one shop left doing auto machine work in a commercial location. For us, the transition to motorcycle and specifically V-Twin was a natural one. We have doubled our staff and typically have a backlog of work year-round.

Having done general automotive work left us with a shop that is better equipped than most motorcycle shops, hence we have about half of our work coming from other businesses, which is a good steady work stream. We have two manual horizontal honing machines that we use for small cylinders, connecting rods from assembled cranks, case races and bushings. Our boring equipment was easily set up to do motorcycle cylinders, and a few fixture plates, made in-house, allowed head work to be done on our seat and guide machines. There are special tools required to do some of this work, but they are easy to find and not very expensive.

Getting more motorcycle-based business is not at all difficult. Your automotive background will serve as an excellent base of knowledge. I am starting to see a demand building for powersports engine machining as well as metric and European street bike work. Due to the decline of the small shop, there is plenty of used equipment available to get you going if you need something like a small boring bar or guide and seat tooling. Any fixtures for holding heads, cylinders or torque plates can be bought new, used or be fabricated.

It has gotten a lot easier to keep the shop clean as well. Speaking of cleaning in general, you will find that motorcycle work will bring a lot less dirt and grime into your shop as well as cutting your cleaning waste down to almost nothing. As far as information, specifications and procedures go, there are many manuals, both factory and aftermarket, available, as well as a ton of info on the internet should you need any shop-based tech help.

Now, let’s say you’re set up and ready to go. Where do you find this type of work? In our particular situation, racing guided us into this specialty, but there are more venues to look at. The demand is so great and volume so high in our area for cycle-based engine machining that we do not take in anything that is not in our particular wheelhouse. Locally, I have also noticed there are not many places to get metric/European motorcycle engine work performed, especially by an experienced machinist. That not being our focus, we are forced to turn those jobs away. I know firsthand, if there was a small engine/ motorcycle/powersports shop in my region staffed by good people who specialize in the metric/European segment, they would do well.

Someone looking to get into this realm could simply call on motorcycle shops in the region around them as well as powersports and utility dealers such as lawn and garden repair shops to build a consistent customer base. As I said before, half of our work comes from established motorcycle shops. Go to some motorcycle events and swap meets to hang out and talk to people to see what they are looking for and if you can help them. You will find, as always, if your work is good and you treat the customer well, word will spread fast and you will have plenty to do.

The most sought-after services are cylinder boring and honing, cylinder head service work like valve and seat work, surfacing, removing broken bolts and studs, and small welding jobs. There are also opportunities in press together crankshaft service. This is an acquired skill that comes from practice. It is better learned from doing it than being taught by someone. If your auto machine shop skills include various press work jobs, then you already have a head start on assembled crank service. Oversize rod and main roller bearings require some horizontal hone skills, which is a simple operation, but must be right on the money to be done correctly, so your automotive experience will come into play.

Another area to consider is parts sales. I can relay to you from my personal experiences that when you are doing specialty work, the majority of customers will buy their job-related parts from you in addition to having you perform the machining. Valves, pistons, rings, gaskets, and other job-specific parts can be sourced in a few days, making your expert work a complete job. This also makes life a lot easier because you have some control of what kind of parts you use, especially when it comes to quality and sizing. After you build up a flow of jobs, you can then determine what parts to keep on the shelf to make sales a bit better.

Due to our shop’s specialty market, we have a complete, full-service motorcycle facility. We have a dedicated motorcycle dyno room for tuning and troubleshooting, a full-service garage area and walk-in retail area to complement our machine and fabrication shop. When I made the decision to go “cycle only” it was for several reasons, but the biggest among them being that the nature of the auto machine business had changed in ways that had driven almost all others in my area out of operation.

I made this change with the idea it would help me survive. However, for us, it proved to be a chance for growth and expansion into the motorcycle industry. I want to make clear that I am not saying the auto machine business has run its course. I am actually seeing an increased demand for automotive machining driven by the performance and restoration scene, but for some of us, changing directions has helped shops like ours continue to operate and grow, as well as provide a much-needed service to the motorcycle culture.

Also, being involved in racing has definitely given us an edge. The skills and experience gained over years of racing and building performance-based V-Twins helped a lot in the transition to where we are now. The relationships we’ve made with fellow racers has helped with growth and recognition, as well as making industry contacts that have proved to be very helpful. Today, finding a specialty or niche seems to be what is helping our industry grow, and in my opinion, motorcycle engines are still a largely untapped source of opportunity. EB