THREAD IT TO REMOVE IT

Solid, smaller-sized dowel pins can be stubborn sometimes. One of the most useful ways I’ve found to deal with the really stubborn ones is to start by putting a heavy chamfer on the outside edge of the dowel with a grinder. Then, I run a die on it. In this case, the dowel is 1/4” OD and the die used was a 1/4-20 NC. Run the die on it as far as you can and then remove it. Lay a washer over the dowel, turn a nut on the dowel until it stops. Take the nut back off, add another washer and repeat until the dowel comes out.

Joshua Hartmann Hartmann Racing and Development Gerald, MO

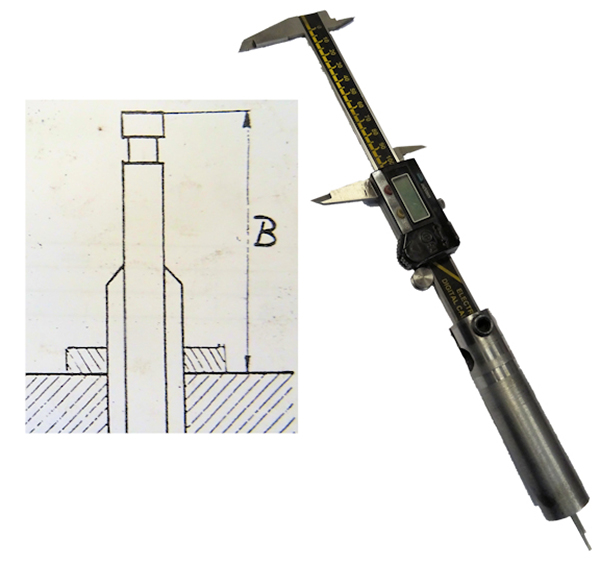

HOMEMADE VALVE HEIGHT MEASURING

I made a valve tool to measure valve tip height as shown in the picture. I use it before cutting and write it down and check it after valve job. It is also very handy when setting new valve seats. It is easy to make. Take a digital caliper, a pipe and screw the two together as shown.

Joris Decker Deckers Motorenrevisie Belgium, Europe

EXHAUST MANFIOLD SURFACING

I grind exhaust manifolds on a dry belt surface grinder. Before I grind them, I bead blast the manifold surfaces to clean off the hard rust and carbon build up first. By doing

this the manifolds grind easier and the belts last longer.

Wes Schell Schell Engine and Machine Gregory, SD

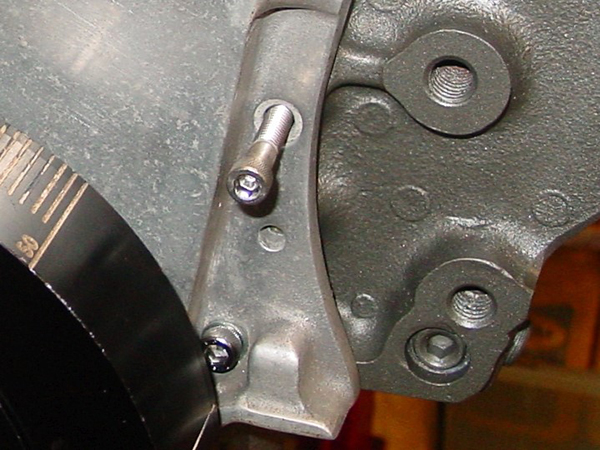

BALANCER HUB SEAL TOOL

Here’s a trick to help center the timing cover crankshaft seal, when the timing cover or block has no dowel pins, or the dowel holes do not fit snug on the pins. Take an old damper and hone the center so that it is now a slip fit onto the crank snout. Use it to hold the cover in place while tightening the bolts. Then, simply slide the damper back off. I use an old aluminum crank hub for big block Chevys, which is lightweight and easy to handle. I save other hubs from balancers that have come apart.

Rich Jones Redline Automotive Competition Engines Davie, FL

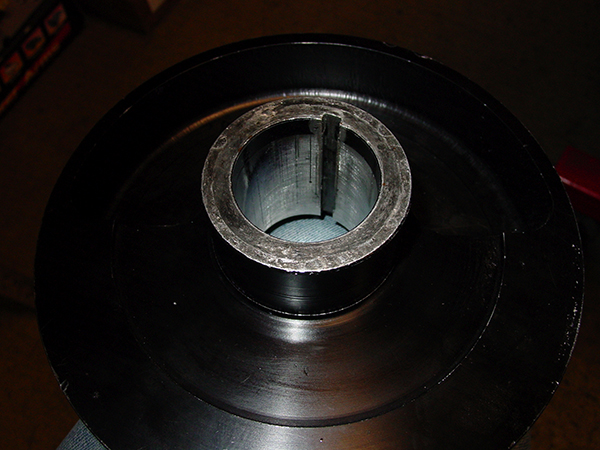

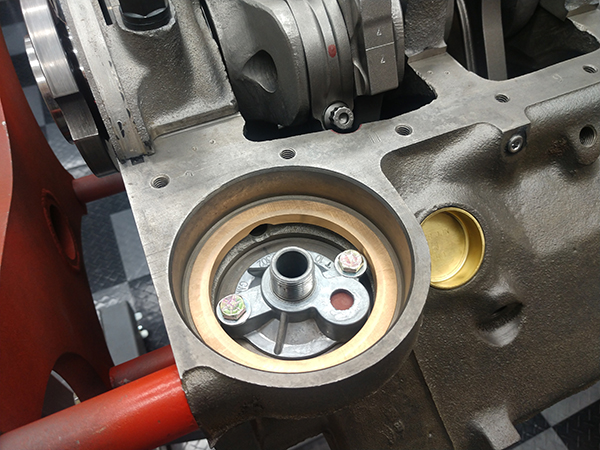

MORE ON BALANCER HUBS

I have several balancer hubs that I’ve honed for slip fit tools. If you have an engine where there is a timing cover index issue from either poor dowel pin alignment or a crank centerline issue, you can still locate it properly. Remove the dowel pins or drill out the holes in the cover for clearance. Then, loosely install the cover and slide the balancer hub on. Finally, tighten the bolts and check for proper seal interface by applying a little assembly grease all the way around the hub’s seal surface. Then, slide it on and back off. You’ll see if the seal witness marks are contacting all the way around. Having external balance hubs with zero press is great for balancing cranks too.

Ron Flood Cedar Machine North Branch, MN

EARLY SPIN ON FILTER ADAPTER

When I restore an early Chevy V8 that used a cannister oil filter, I like to update for a late-style, spin-on filter. I machine up a ring 3.800” OD with a 3.075” ID, .300” thick. I bore out the block to except it. I’ve used aluminum and bronze and just plan so the top of the ring is the same height as a late 350. I also rethread the adapter mounting holes for a 5/16” bolt. I can then use the late spin on oil filter adapter. I like it better than the oil filter adapter commonly used, and customers do too.

Randy Torvinen Torvinen’s Machine Shop Menahga, MN