REAMING OIL PASSAGES

I like to use reamers to clean out oil passages in old engine blocks that have sat around for a long time and are rusty. If you use a +.001” oversize reamer, you will have perfectly clean oil passageways.

Dave Matton D and D Auto Machine Bloomington, MN

ENG GAP ESCAPE PATH

I often feel that people will gap the top oil ring rail improperly. The top oil ring rail needs to have a gap that is the same as the 2nd (scraper) ring above it, at operating temp. Gapping it the same is a safe adjustment. The tapered second ring gap will open as the face seats, but close some at operating temp. This completes the path for any “pressure spike” to escape via the oil ring groove drain holes. If the top oil rail is tight, it will effectively have the same detrimental effect as having the scraper ring tighter than the top (compression) ring, upsetting the ring seal. A properly working ring package needs a controlled path for pressure spikes to escape, to prevent disrupting sealing. This is especially important with gas-ported pistons or rings. Bonus tip, grind 3-4 at a time to increase stability and don’t have a lot of the fly end hanging out. This way they won’t grab the wheel and bend.

Ron Flood

Cedar Machine

North Branch, MN

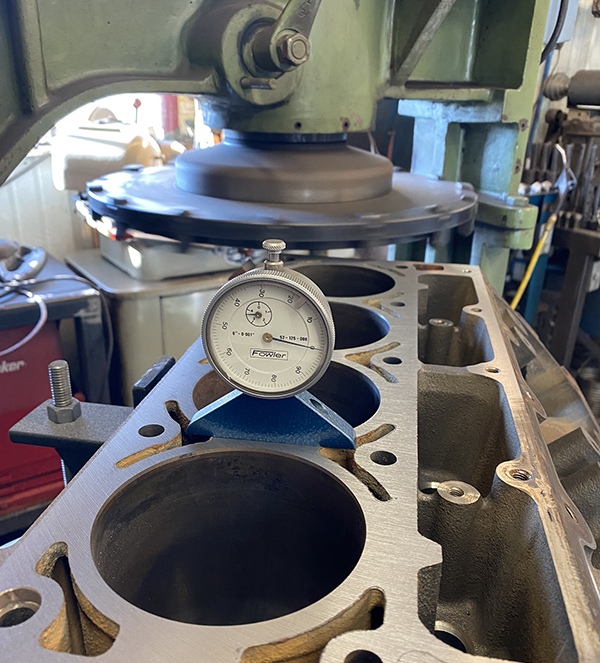

EASY SQUARE DECK

When square decking blocks I simply take a measurement from each corner of the deck down to the parallel support bar. Choose the lowest side and deck it first. Then, roll the block over and equal that side.

Bruce Serene

Hillsboro Racing Engines

Hillsboro, KS

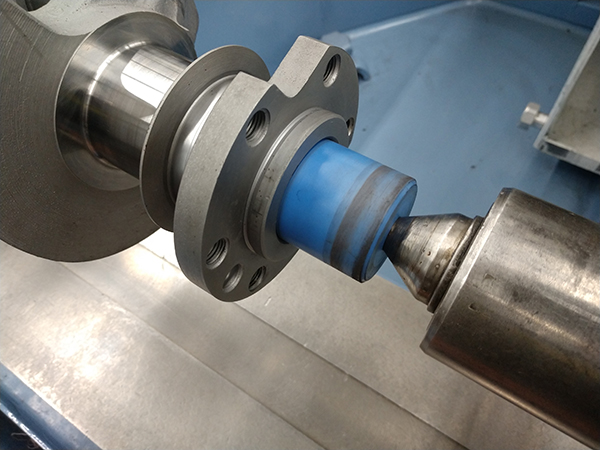

QUICK CRANK CENTERS

To make it quick and easy to mount cranks in the grinder, and especially the lathe for polishing, I made inserts for various engine families. Delron, or that type of material, works great and I give them about .001” clearance so they are reasonably stable.

Randy Torvinen

Torvinen’s Machine

Menahga, MN

SHARPER SCRAPERS

I like to keep my super scrapers nice and sharp. Here’s an easy little way to touch them up. I squared up a piece of scrap steel in my mill and drilled the hole in the same setup, so it’s nice and square. I drilled the hole just under the .375 tool post size for my boring bar diamond lap, then honed it to size for a nice tight slip fit. Put the fixture on the post, set the scraper on the diamond lap so it’s sitting flat, then tighten the clamp. Sweep it back and forth with the wheel running a few times and check your edge. It doesn’t take long and they’ll scrape like new again!

Jake Sampson

Sampson Racing Engines

Inver Grove Heights, MN

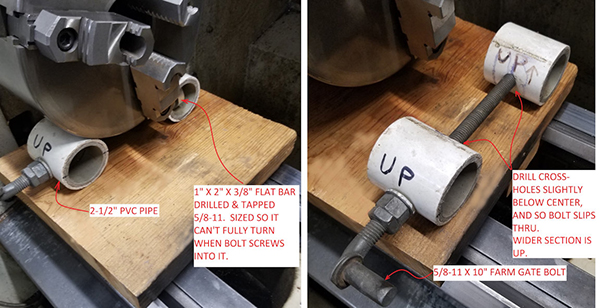

CHUCK SUPPORT

I made this simple chuck support to help make changing chucks on my lathe and crank grinder much easier. Made from PVC pipe, a farm gate post bolt (or all-thread rod), and hardware, this adjustable chuck support lets the chuck slide off and on the spindle with ease. Used with a wooden board to protect the machine’s ways, swapping chucks is quick and effortless. No more struggling to lift and hold a 6”-12” heavy chuck up to the spindle. The gate bolt is tightened by hand to draw the two PVC pipes together, raising the chuck or loosened to allow the PVC pipes to separate, lowering the chuck. The PVC pipes move relatively easy side-to-side on the wood, allowing for effortless alignment and support during chuck installation or removal. Clamping a length of tubing in the chuck makes a convenient grab-handle for safer chuck handling to and from the machine.

Tom Nichols

Automotive Machine and Supply, Inc

Joshua, TX