Locking the camshaft and crankshaft down together provides an accurate method to ensure the motor will remain in time during the repair process.

The Camshaft Alignment Kit (37410) from Lisle Corporation is perfect for servicing the timing belt, chains, head gaskets or other valve train repairs on Ford, Mercury and Mazda vehicles.

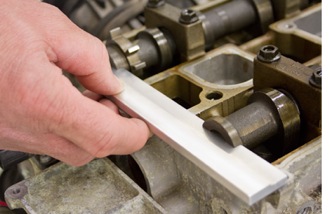

The kit comes with an aluminum camshaft holding bar, plus one short top dead center (TDC) timing pin and one long TDC timing pin.

[inpost_gallery post_id=4879 group=”1″]

Applications:

The camshaft bar and long TDC timing pin are used on 2.0L DOHC Zetec engines found in 1994-2003 Ford and Mercury vehicles.

The camshaft bar and short TDC timing pin are used on 2004-2012 2.5L DOHC, 2.3L DOHC 4V and 2.0L DOHC engines that are found in Ford, Mercury and Mazda vehicles.

The camshaft alignment bar can also be used by itself on 2.0L DOHC engines in 1993-’94 Ford Probe models.

Instructions:

Turn the crankshaft clockwise to top dead center on the compression stroke. Insert the alignment bar into the slots on the ends of the camshafts.

Remove the plug bolt on the side of the engine block near the crankshaft and install the TDC timing pin.

Locking the camshaft and crankshaft down together provides an accurate method to ensure the motor will remain in time during the repair process.

For a video on this tool, click here.