Camshaft Selection

“What camshaft should I use?” How many times have you been asked or heard that question uttered? Why is it so difficult to choose the “correct” camshaft for an engine build? What separates one camshaft design from the other? After all, isn’t it true that a camshaft opens and closes valves? Simple, right? Well let’s

Understanding Engine Treatments – What components can benefit from coatings? You may be surprised at the treatments available.

If you were to place technological advances on a scale, I would say that engine coatings would probably rank near the top. Engine coatings have a lot of merit, but unfortunately are often overlooked. Engine coatings have a reputation that they are only beneficial for racing applications. Yes, coatings are regularly applied and highly appreciated

Camshaft Class is Back in Session

A theory prevails in which a cam lobe that opens to maximum lift and closes instantaneously is quintessential for maximum power and torque operation. Two problems exist with this premise. First, it’s highly impractical due to current technology. Second, this theory discounts a fundamental dilemma that air has momentum, and this must be utilized to achieve

Reusing, Reclaiming, Remanufacturing – Whatever you call it, it’s how the industry recycles parts and components

No matter what kind of engine builder or remanufacturer you may be or what applications you build for, at some point in time you’re going to run into a situation where a used engine part or component will come in handy. You’ll reuse, reclaim or remanufacture it for your specific job. Whatever the reason may

Form, Fit & Function – Valvetrain Components Must Work in Harmony

The upper valvetrain is one of the most critical components in an engine build, so it’s essential you choose the right parts for the application and install them correctly. Here are some suggestions for getting things right: DON’T USE “STANDARD” LENGTH PUSHRODS Many variables can affect the length of the pushrods that are required to

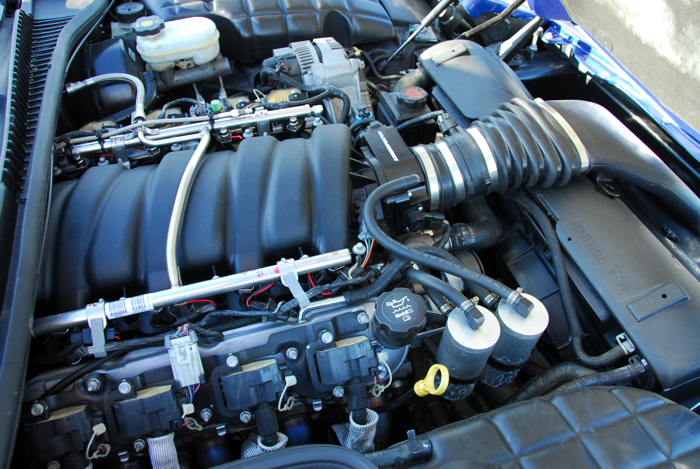

Choosing the Correct Camshaft – Bangin’ on the Bumpstick

There are numerous aspects involved in designing an engine combination. Displacement, compression, airflow, etc., and it is the camshaft’s job to ensure that all of these work together properly to achieve optimum performance. That’s why the cam is often referred to as the “brain” of the engine.

Jasper Completes Renovation and Relocation Project

Jasper Engines & Transmissions has completed the renovation and relocation of its Gas Division within JASPER’s Wernsing Road remanufacturing facility. The Lifter Department was the last group to move into its new position, joining other Gas Division support groups on the main floor of the facility. “We now have all our remanufacturing on one level,”

There’s No Simple Formula to Choosing the Perfect Camshaft

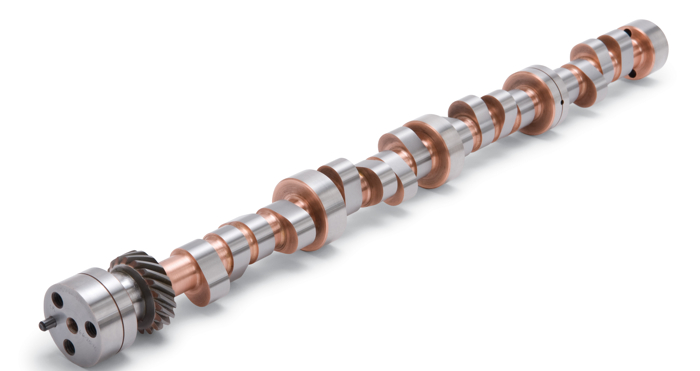

The camshaft design affects valve timing, compression and the engine’s ability to breathe. From pistons to manifolds, valve grind, piston pin offset, rod length, etc. Once the camshaft has been tabbed correctly for the application, the rest of the build can focus off that selection.

Edelbrock Rollin’ Thunder Camshaft For Chrysler Gen 2 Hemi Engines

Edelbrock has a new Rollin’ Thunder camshaft for Chrysler 426-572 Hemi engines. Edelbrock Rollin’ Thunder hydraulic roller camshafts are designed to improve horsepower and torque, produce a great sounding performance idle and provide sufficient vacuum.

Super Class Act: Super Comp Engines and Drivers are a Different Breed

The three Super Classes are the only ones allowed a throttle stop. In the beginning of the Super Class fixed index racing history, racers had to set up the car and physically control their driving in order to run as close to the index as possible. When the throttle stop entered the picture, things changed drastically.

Building Trophy-Winning, Comp-Grade Engines

While the victor of multiple racing events usually gets all the attention, what about that unsung hero under the hood? A driver is nothing without a dependable engine that can go the distance. Here you’ll find how an engine builder can empower a talented driver, and some specific tips on tailoring an engine setup to a wide range of applications.

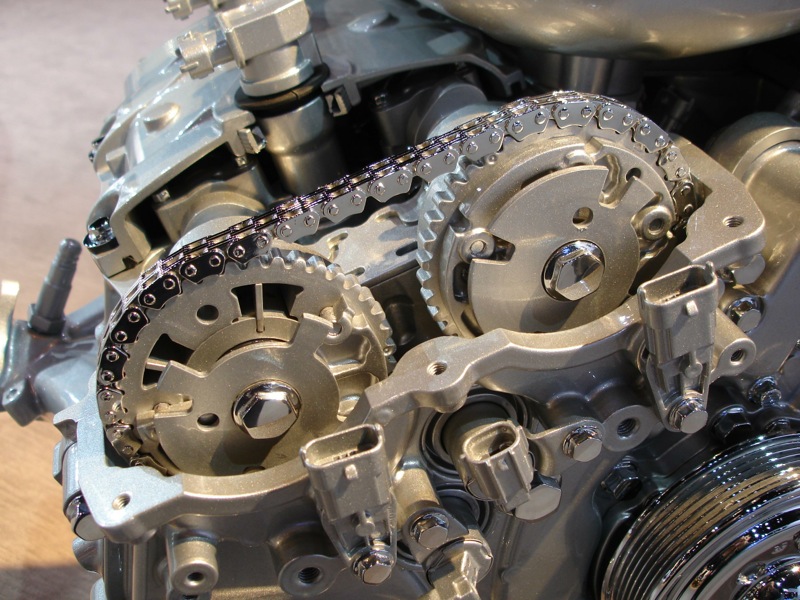

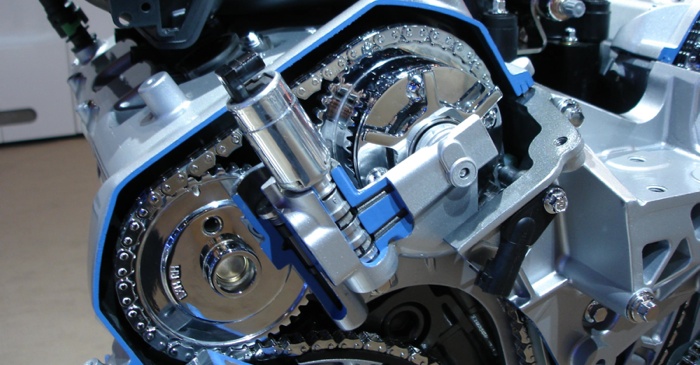

The Complexities of Modern Timing

Let’s face it: timing used to be relatively easy. These days, however, as with most every other engine component, the technology and innovation that leads to more fuel efficiency and performance also means increased complexity with timing components.

Camshaft Selection and Design

Choosing the right cam from all of the possibilities that are out there can make a significant difference in how well an engine performs. It’s all about balance and correctly matching the cam with the cylinder heads, compression ratio, intake and exhaust systems, and RPM range where you want the engine to produce the most torque and horsepower.

Timing Components

For metal parts to rotate, move, lift, bend, sway and – hopefully – not touch multiple times per second, every minute of every hour the engine is running takes more than just good enough – it takes precision that Swiss railroad conductors would envy. While everything in the engine has to precisely fit and accuracy is key, nowhere is precision more critical than in the timing.

Edelbrock Rollin’ Thunder Camshaft For Small-Block Chevrolet Engines

Edelbrock is now offering a new Rollin’ Thunder camshaft for small-block Chevrolet engines. Edelbrock Rollin’ Thunder camshafts are designed to improve horsepower and torque, produce a great sounding performance idle and provide sufficient vacuum.

Choosing the Right Camshaft for a Performance Engine

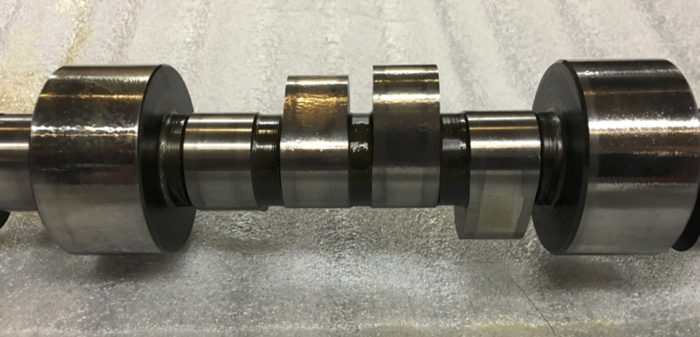

A camshaft is nothing more than a cast iron or steel shaft with a series of lobes strategically placed along its length. Each lobe opens and closes a valve by moving a lifter, pushrod and rocker arm, or in the case of an overhead cam engine by moving a cam follower or direct valve action. However, choosing the right camshaft is not only the cornerstone of building a performance engine, but also its centerpiece.

Crane Cams Crank Trigger Distributors

Crane Cams has announced the addition of Crank Trigger Distributors to its race billet distributors line. The four new part numbers are equipped with a large diameter, low profile distributor cap. This design helps avoid clearance problems. In addition, the caps are manufactured with solid brass lugs, which enable the transfer of the maximum amount of spark energy.

Choosing the Correct Camshaft for the Build

Choosing a particular type of camshaft for an engine build is an important decision that has to be made before any other parts are ordered or machined. Choosing a cam requires answering some basic questions, the most important of which is the engine application itself.

Company Innovations

While technology in general was the primary answer to what innovations helped grow the industry over the past 50 years, when asked about innovations within their own companies that have helped the industry, the answers were more specific to certain engine parts. “Over the years a number of Sunnen innovations have been standards of the

Just in Time – Addressing Timing Component Replacement and Upgrades

The timing components that drive a camshaft affect valve timing, ignition timing (if the engine has a cam-driven distributor), compression, engine performance and fuel economy. Because of this, the timing components must be in good condition with minimal wear and slop, and they must be durable enough to maintain accurate timing for the service life