If the camshaft is considered the brain of an engine, most professional engine builders have dubbed the crankshaft as the heart. Like the rhythmic change of pressure in blood vessels provided by the heart, the crankshaft controls the steady rhythm of the cylinders’ up and down movement, and therefore, the rest of the engine. Similarly, it allows for oil to be pumped (like a heart) into its center and to exit from rotating journals located under every rod and main bearing.

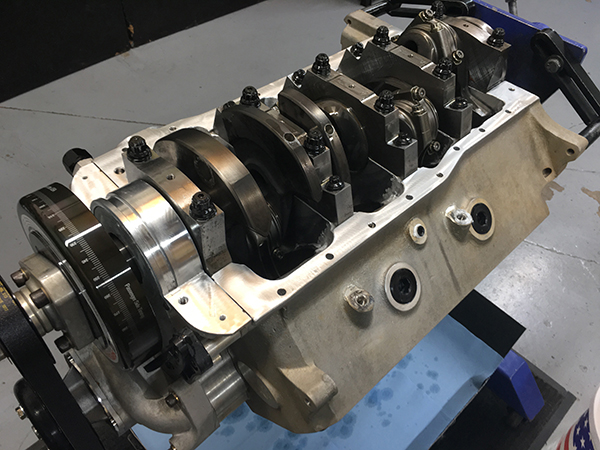

While there are many components that will cause an engine to die if removed, the crankshaft is arguably one of the most important pieces as its regular motion retains the swift functionality of the whole system. As the largest and heaviest moving part within an engine, there’s no doubt the crankshaft is the foundation of which the internal combustion engine is built.

For that reason, the crankshaft is typically the first piece sought after by machinists who are building an engine from the ground up. The fact that they are subjected to very high dynamic loads of force when the engine is in use means builders need to diligently research what crankshaft works best for their application.

Because of the variability of crankshafts that can be purchased and the way it influences the engine being built around it, the crankshaft market is always changing and evolving. So, what’s popular in the crankshaft market right now? It’s hard to say as today’s performance industry is split more than ever between professional machinists and enthusiast builders, but that enthusiast market has grown so much that it can’t be understated. Even in the past two years, Covid has grown the segment exponentially.

“The past few years has turned the industry upside down,” says Alan Davis of Eagle Specialty Products. “We thought Covid was going to make this sort of ‘long winter,’ but we saw just the opposite. Instead of demand dropping, it skyrocketed.”

Eagle Specialty Products produces high-strength connecting rods and crankshafts for racing engines across the country. The Mississippi-based company also provides full rotating assemblies including crank, rods, pistons, rings, and bearings for many popular engine combinations.

Recently, Eagle Specialty sold out of a number of products (including crankshafts) in a short amount of time. The company has always kept a large inventory on hand to allow for fast delivery times, but with production rates at 250% of what they were in 2019, they’re still selling fast for several different applications.

“While the mainstay is the good ole Chevy small block, we have seen the Ford 4.6L and 5.0L gain round, as well as the modern Chrysler Hemi,” Davis says. “The Chevy LS is here to stay and continues to dominate the modern engine market.”

Davis noted that while there are a few new crankshaft products on the drawing board, there are so many existing orders that it has been hard to devote enough production time to new development.

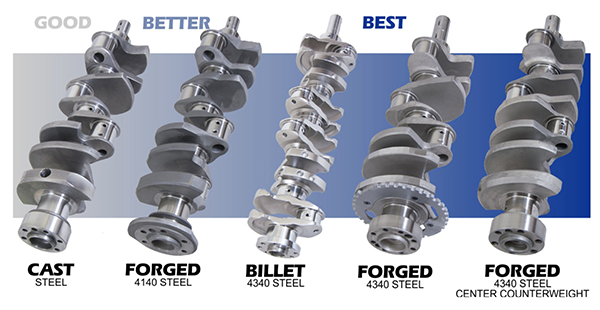

Eagle Specialty offers a range of cranks for various performance outputs, including cast steel, forged 4140 steel, billet 4340 steel, forged 4340 steel, and forged 4340 steel center counterweight. These offerings fill the area of motorsports that Eagles Specialty is most entrenched in, grassroots racing and streetcar enthusiasts.

Cast cranks can support up to 500 hp in a small block and 700 hp in a big block, while the forged 4140 forged steel can hold up to 1,200 hp, and the 4340 steel offerings have been used in engines approaching 2,000 hp. While they now offer billet 4340 steel for short-run production where the costs of a forging are not viable for the quantity produced, the lower-strength cranks are what sell better to enthusiast builders with lower horsepower goals.

It’s an ongoing debate between manufacturers and builders alike whether billet or forged metal cranks are stronger, but the increase in materials and labor over a forged crank means that billet is almost always significantly more expensive. Billet offerings are whittled away from the solid piece of metal bar it’s originally crafted from, as opposed to the twisting and pounding done to shape a forged crank.

This makes billet more attractive for one-off custom cranks, hence the raised price tag. As such, billet has always been the mainstay for the upper echelon of engine builders and hot rodders, and crank manufacturers such as Callies are there to support those efforts.

“All of our ULTRA Billet lineup is made from EN30B and Timken 4330 forged steel, and that’s what these guys want for their big block Chevy and LSX applications,” says Brook Piper of Callies Performance. “There are some really high-dollar materials out there that are slightly strong, but you can’t really quantify the performance gain relative to the big price hike. We sell to a lot of drag racers in Top Fuel and Circle Track racing and these work great for their high-horsepower applications.”

While one-off, custom billet cranks are a huge slice of the Callies pie, they have seen a recent influx of enthusiasts seek their other product lines. In particular, their line of Compstar forged steel crankshafts have seen a major uptick since Covid, especially in the diesel market.

In general, the crankshaft industry has overtime settled down to a steady pace, with cranks being stronger than ever. Engine builders often have steady orders where weights and journal sizes stay the same and manufacturers tend to have a tried-and-true steel material. It begs the question – is there any new technology on the horizon?

Although the practice is not particularly new, eight-counterweight or center-counterweight crankshaft designs have been some of the hottest trends in the industry. Callies is soon introducing an eight-counterweight forged crank for the Ford 302 and 351 small block, as well as the Ford Godzilla and the Chrysler Gen-III Hemi.

Eagle Specialty Products has also began offering more center-counterweighted crankshafts than ever before, with the first ones to roll out for the Chevy big block and LS.

With engines making more power than ever, eight-counterweight designs are specialized to reduce crankshaft flexing at the extremely high rpms that these higher-stroke engines are running at. While they don’t necessarily improve performance, reducing crankshaft bend will inevitably improve the longevity of the crank and ancillary components surrounding it.

Being the heart of an engine, longevity is of utmost importance. Whether you’re running an LS, big block Chevy, small block Ford, or any other type of engine, it’s important you know the ins and outs of today’s crankshaft offerings in order to find the right fit. EB