STOP THE FLOW

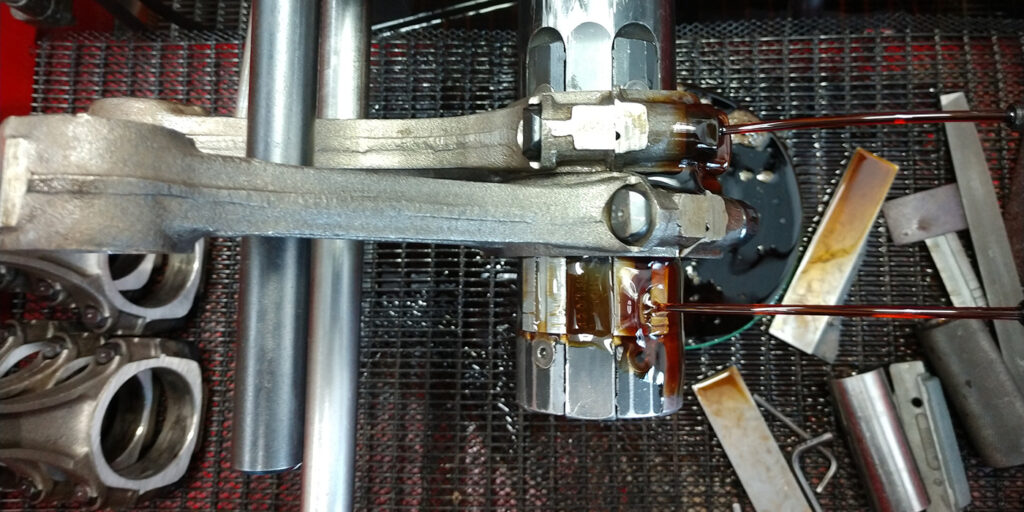

I line up the oil stream on my rod machine to where I want to stop the stroke. I try to over stroke approximately 1/2 of the rod width to keep the shoes from wearing unevenly.

Randy Torvinen

Torvinen’s Machine Shop

Menahga, MN

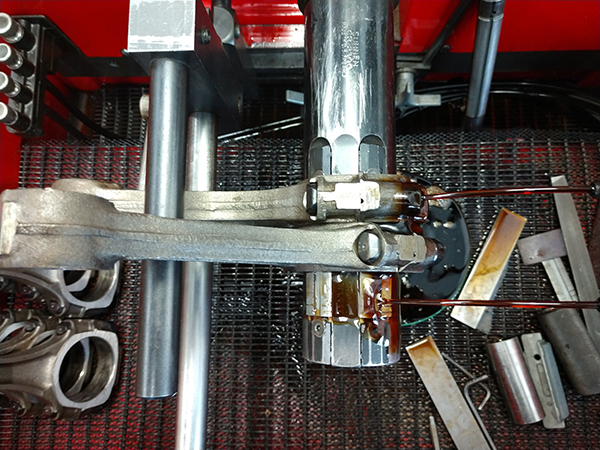

O’RING END STOP

When honing some parts on the rod machine, I use an o-ring on the mandrel as a visual end stop for proper over stroke. This really helps on things like motorcycle cases and multi-rod assemblies to ensure proper mandrel over-stroke coverage. It also helps with pistons when they’re upside down and you can’t see the inside end of the stone.

Ron Flood

Cedar Machine

North Branch, MN

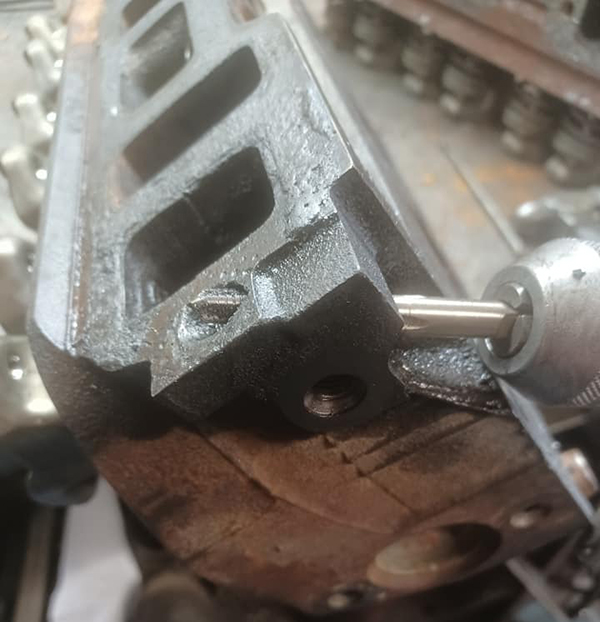

THREAD DEPTH MARKER

When tapping tapered pipe thread for oil or coolant passage plugs in blocks and cylinder heads,

it is important not to tap too shallow nor too deep. A length of soft copper wire, twisted around the tap,

works much better than tape or a Sharpie mark to indicate the proper depth.

The copper wire stays in-place for hundreds of uses, saving engine builders time and frustration.

Tom Nichols

Automotive Machine & Supply

Joshua, TX

FINDING YOUR CENTER

One of the most challenging jobs is the 302-351W cylinder head stud removal that fastens down the intake manifold. It rusts and sits at an angle, which makes it almost impossible to center a drill bit for removal. The solution is to drive a 1/4-inch roll pin under the cylinder head, this will make passing a 5/32 drill bit through perfectly centered. Then you can try an “easy-out” or an E-drill bit to get most of the material left. Then pass the 5/16 tap, as shown in the picture.

Luis Guzman

Technomotors

El Paso, TX

INSTALLER EXTENSION

The harmonic balancers on the 5.0L Fords are deep and need extra space. I used a small PVC pipe coupler to extend the reach of the installer. It is cheap, lightweight and works great.

Pete Ross

Petes Car Care

Rochester, IL

FITTING IN A SIZE SMALLER

After file-fitting piston rings to get the perfect end gaps, we need to remove all burrs left from the filing process. Despite all our best efforts, sometimes we install a ring on the piston and still notice a little drag when testing for rotation. I like to test fit my ring chamfering and rotation on a smaller bore piston with the same ring thickness to check for drag so that I am not removing, reinstalling and overextending the rings for a second time if I must touch up my ring chamfer.

Dave Matton

D and D Auto Machine

Bloomington, MN