Clean up in aisle nine! I used to poke fun at “grocery getters.” These were cars you might see just driving to the market, or back and forth to church. You had to be careful, though, because you never knew what was under the hood of these cars. They just might put their foot down and leave you more than a little embarrassed.

Now, looking back and comparing those “grocery getters” to the street cars of today, we all just might have been driving a grocery-getter. When import cars began to hit the scene, they weren’t known for their brute acceleration, but they had the edge on handling. It didn’t take long for them to catch up in horsepower either, and suddenly makes like Honda, Mitsubishi, Nissan and Toyota were making a mark at the dragstrip.

Back then, race cars were far more advanced than street cars and when it came to oiling systems, if you were running a dry sump, it meant you were at the top of the racing food chain. Indy cars, Formula 1, NASCAR, Pro Stock drag racing, circle track – these are just some of the cars that ran dry-sump systems.

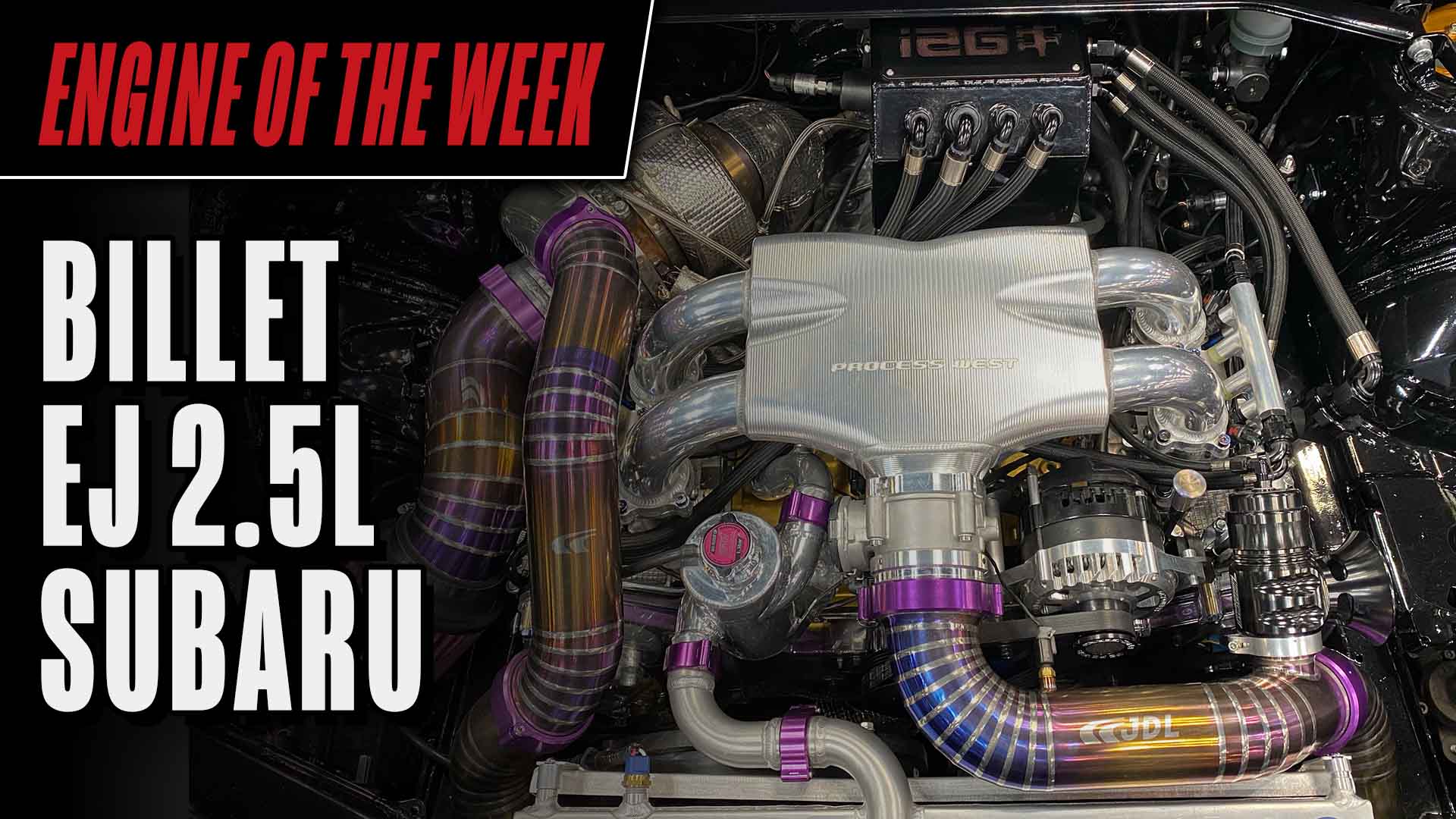

When the import scene exploded thanks to the motorsport of drifting coming to the States, and plenty of road racing uses as well, seemingly overnight the performance and handling of these import cars blurred the line between street and racing. Many of the popular import engines were proving themselves as bulletproof and as iconic as some of Detroit’s favorite blocks.

As their performance on and off the track continued to grow, their factory wet sump systems simply couldn’t handle the performance and the development of dry sump systems for the popular imports was in high demand. But why a dry sump?

It’s simple. Wet sump systems are what is on the majority of all cars on the road, and they work just fine for that type of driving…you know, half-gallon of milk, head of lettuce and don’t forget the sour cream. A sump is a reservoir by definition, and a wet sump just means the reservoir in the oil pan is where the oil is stored and theoretically where it returns to after being pumped through the engine, so the oil pump can pick it up once again.

But throw in high rpm, acceleration and deceleration forces, then lateral forces from hard cornering, and all of a sudden, there’s no oil for the pump to pick up. It’s in the top of the engine or on the sides of the pan, and the next thing that happens can only be bad. The resulting cavitation, which occurs any time there is not enough oil to supply the needs of the pump, can not only starve the engine of oil, but damage the pump as well. In addition to these inherent problems with a wet sump system, the oil in the pan splashes on the crankshaft and creates drag, another obviously undesirable affect.

Dry sump systems eliminate these problems. A dry sump system stores the oil in a separate reservoir outside the pan and utilizes an external oil pump, which is driven the majority of the time off of the crankshaft via a belt system. There are some cam drive systems available too. The removal of the pump and/or pickup from inside the pan allows a much shallower pan to be used, allowing more ground clearance for a lowered vehicle, or allowing the engine to be mounted lower in the chassis.

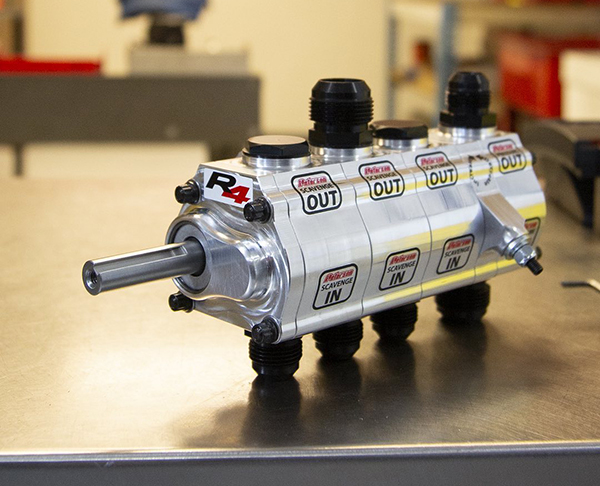

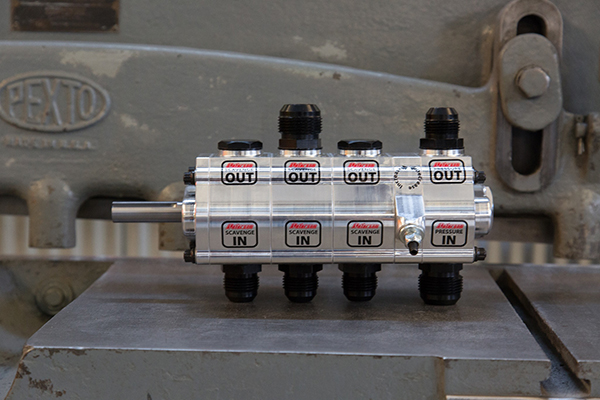

Dry sump systems have multiple stages, two being the minimum. The first stage is the pressure pump and the remaining stages, commonly as many as five or six, draw a vacuum on the crankcase and scavenge the oil returning to the pan or from other areas of the engine. Not only is all the oil immediately returned to the external reservoir to provide ample supply to the pump, but there’s no oil to create drag on the crankshaft, and the vacuum created in the crankcase also creates a power advantage.

A few of the big dogs from the import scene that commonly employ a dry sump system to keep up with performance are as follows:

Mitsubishi 4G63

The Mitsubishi 4G63 was first introduced in 1980 as a 4-cylinder 2.0L naturally aspirated en-gine, with the turbo version coming to market in the late ‘80s. They feature cast iron blocks, aluminum cylinder heads, forged steel crank and rods and cast aluminum pistons. Depending on the variation of engine, they were available with an eight-valve single overhead cam (SOHC) cylinder head, a 16-valve SOHC cylinder head, or two different versions of a 16-valve double overhead cam (DOHC) cylinder head.

The success and durability of the 4G63 led to over 40 years of production, and these hot little engines have been pushed to well over 1,000 horsepower and have been seen on the dragstrip powering cars into seven and 8-second quarter miles.

The common oil system problems with the 4G63 are high-rpm cavitation and excessive blow-by in the crankcase, causing oil to remain in the cylinder head. Three- and four-stage dry sump systems are popular for these engines, and it’s common to add scavenging for a remote turbocharger or to scavenge oil directly from the cylinder head.

Toyota 2JZ

Toyota released the 2JZ in 1991. It was a 3.0L inline 6-cylinder engine with an 86mm bore and 86mm stroke, cast iron block and forged crank and rods. It was available as a naturally aspirated version or a twin-turbo version, the latter was and still is a force to be reckoned with. The engine blocks feature a fully closed deck, allowing them to handle massive boost pressure. There were a few different variants, but all received variable valve timing in 1997.

One of the bigger differences is the connecting rods. Some variants had rods that could only handle approximately 500 hp, where most variants had rods that could handle an astounding 1,000 hp, making them incredibly popular for the addition of larger aftermarket turbos.

Horsepower in the 400-500 range is easily attained with a 2JZ, and some of the highly modified versions have reached the 2,000 horsepower mark. The 2JZ has definitely earned its “bulletproof” reputation. The most common oil system problem, as with many wet sump systems, is cavitation. On the 2JZ it’s usually around 6,500 rpm. Since many of these modified versions are spinning closer to 11,000 rpm, the need for a dependable dry sump system is clear.

It’s not uncommon to see a seven-stage system with three pan scavengers, two vacuum scav-engers and one turbo scavenger.

Nissan RB26

The Nissan RB26 is widely known as the rival to Toyota’s 2JZ. The RB26 is a 2.6L inline six-cylinder cast iron block, aluminum head engine. Although the RB series was first produced in 1985, the RB26 variant was first available in 1989. It featured a DOHC with four valves per cylinder, forged crank, rods and pistons, and was available as a normally aspirated 10.5:1 or twin-turbo 8.5:1 version.

A unique feature of the RB26 was six individual throttle bodies, giving it plenty of air to breathe. Upgrading to a single turbocharger versus the original twin-turbo setup is a popular modification and cranking out as much as 1,000 hp was not a problem for the stock internals. With the right modifications, it’s not uncommon to reach the 2,000 hp mark with a Nissan RB26.

Early on, oil pump failures were common in which the oil pump gears would fail under heavy loads, and even though the issue was addressed by the factory and a number of aftermarket performance wet sump oil pumps are available, oiling system problems continued to arise where extreme horsepower and performance were required. In addition, the RB26 also had a common problem with oil drain back to the pan. Especially with any high-flow pump, the oil drains do not offer a large enough flow and oil builds up in the cylinder head, causing both oil starvation and crankcase ventilation problems.

Dry sump systems have successfully eliminated these oiling problems in RB26 engines and are typically four-stage systems with a heavy focus on evacuating the oil from the cylinder head.

Honda B-Series

Honda B-series engines are nothing short of legendary in the world of import performance. Not only are they incredibly reliable, but they produce an impressive amount of power for their relatively small displacement. The two most popular variants are the B16 and B18 – 1.6L and 1.8L engines, respectively. The B16 first appeared in the U.S. in 1989 and the B18 followed with its first appearance in 1990. It’s a B-series engine that holds the title of first production engine to produce more than 100 hp per liter.

Much of the success of this platform can be attributed to excellent design characteristics, in-cluding their combustion chamber design, plus large intake and exhaust ports and valves. Hon-da’s VTEC system, which is electronically controlled variable valve timing, also played a huge part in the success of these engines.

The B-series engines saw a number of different versions over the years with changes in bore, stroke, compression ratios, and intake configurations. Swapping parts between the various engines is popular and yields impressive results, but it takes the seasoned knowledge of a true B-series specialist to be able to rattle through all the options and the pros and cons for different combinations.

A horsepower range of 200-300 is common for these engines and easily attainable, with some stock engines already close to 200 hp. Racing engines have eclipsed 1,000 horsepower with ease. While the B-series is known for a dependable oil system, you can’t escape the need and benefits for a dry sump, especially with these lightweight potent powerplants ending up in almost any small, lightweight make you can think of, and proving their potential on the street and on the track.

Even though the B-series only saw a 12-year run and was replaced by the K-series engines, complete dry sump kits are still available.

Any time you add an accessory that is driven by the crank pulley, you risk interfering with an-other. Since so many of the imports that feature one of these iconic engines see use as daily drivers, many of the dry sump kits are optioned so you can retain the air conditioning on the car, just in case you need to keep the milk cold on the way home. EB