PBM To Host Camshaft Design and Development Seminar at PRI

Noted speakers Steve Tanzi of Erson Cams and Darin Morgan of Profiler Performance will moderate an open discussion about cylinder head airflow and camshaft performance. Morgan and Tanzi will focus the discussion around how cylinder heads are affected by camshaft lift and duration and other factors that influence today’s racing heads and cams. Darin Morgan

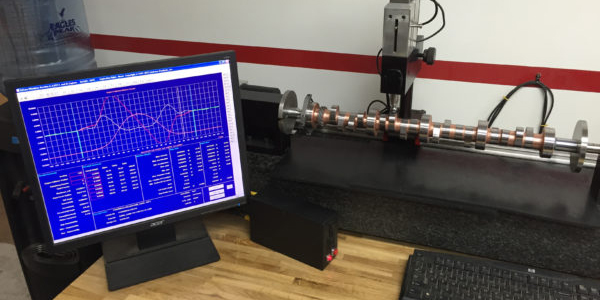

Understanding Camshafts – Part 3 (Cam Design)

Now that Steve has run through lobe shapes and cam cores, you’re ready to put it all together in order to understand what goes into designing a custom camshaft, and the reasons behind certain decisions. If you missed Part 1 or Part 2, view them at the links.

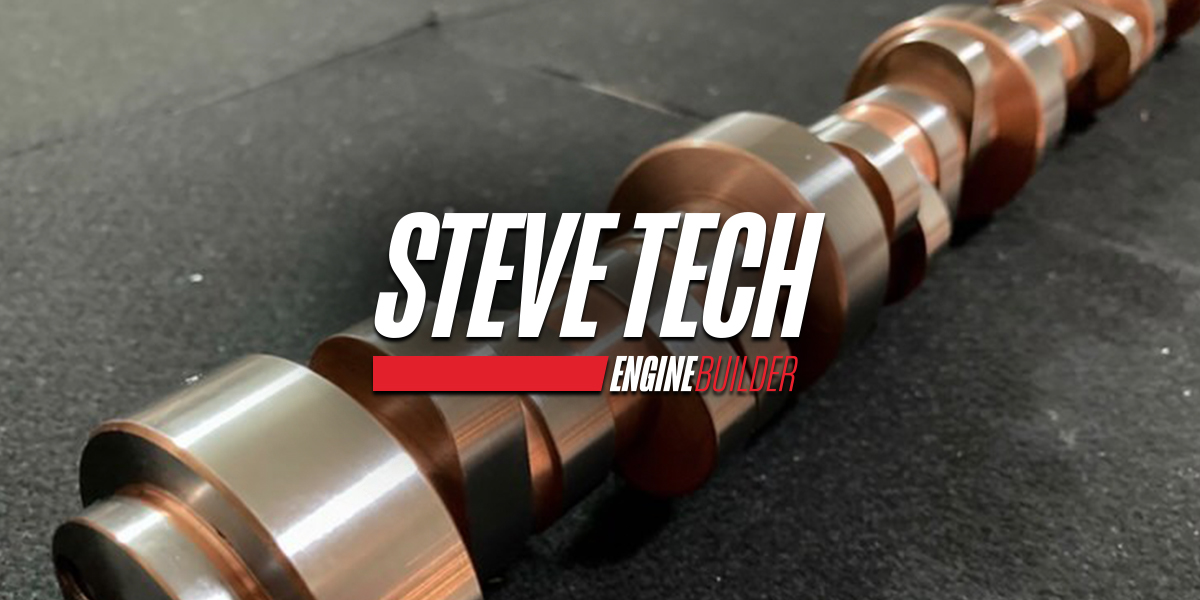

Camshaft Selection and Design

Choosing the right cam from all of the possibilities that are out there can make a significant difference in how well an engine performs. It’s all about balance and correctly matching the cam with the cylinder heads, compression ratio, intake and exhaust systems, and RPM range where you want the engine to produce the most torque and horsepower.

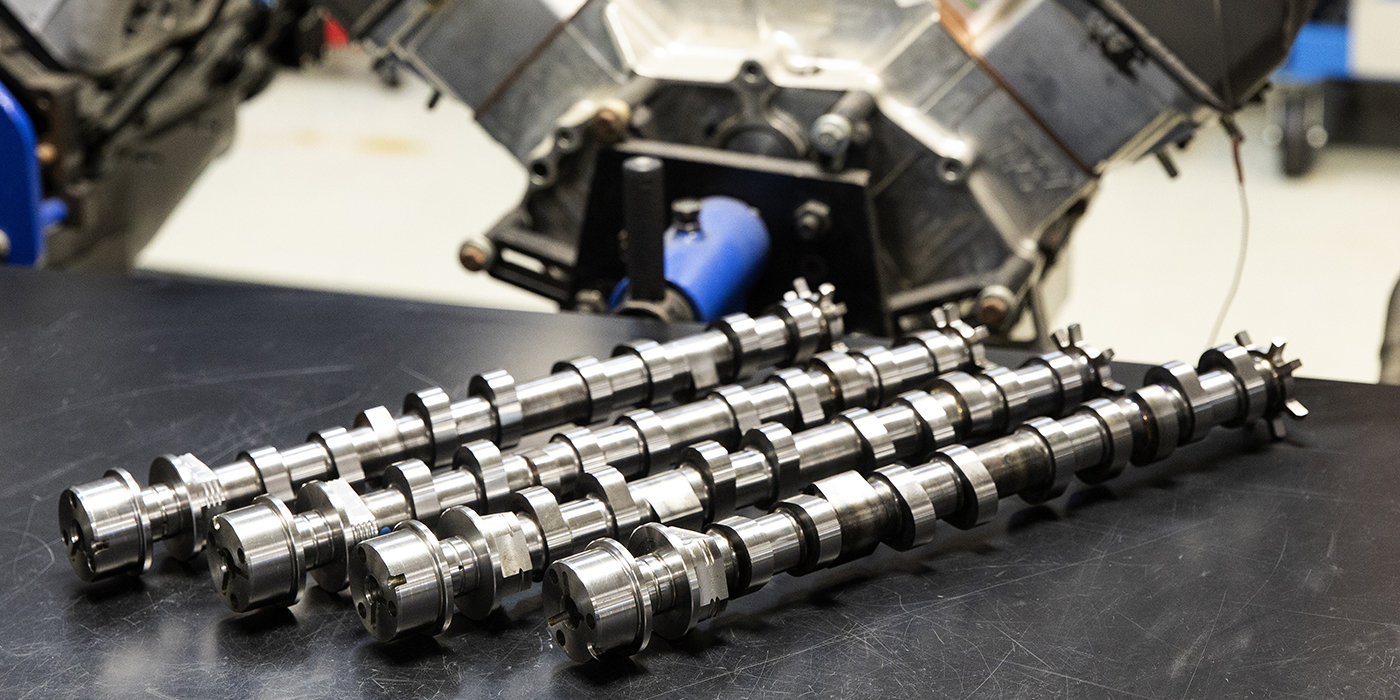

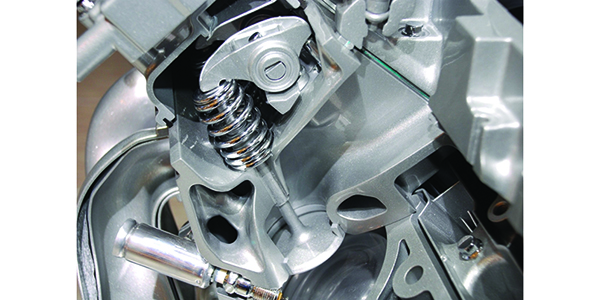

Camshaft and Lash Adjuster Design Change for Ford 5.4L-3V Engine

Do not use 2005 MY parts when servicing a 2004 MY engine, or 2004 MY parts when servicing a 2005 MY engine. If parts are intermixed during a service repair, the engine may exhibit noises on affected cylinders and engine damage may result. ACTION Order and install parts for the correct model year engine. The

Summit Racing Big Block Chevy Hydraulic Roller Camshafts

Made in the USA from billet bearing steel and finished on Landis grinders, the cams have a 4/7 firing order.

Summit Racing Pro SBC Turbo Camshaft

Designed to fit 1986 to 2002 factory roller cam blocks, these American-made hydraulic roller cams feature ultra-modern lobe technology compatible with modern turbochargers.

Custom Camshaft Theories

If you go back to the 1900s to 1940s, the common place to start WAS the camshaft lobe. Engineers and engine designers drew one circle for the base circle, one for the nose, and then connected the two with arcs in-between. Eventually that was improved by shifting their focus to the lifter or tappet rise from the base circle.

Jesel Camshaft Belt Drive Systems

Built with the finest materials available, our Camshaft Belt Drives feature several performance and valve train stability enhancements over traditional timing chains and gear drives. The Gates patented High Torq Drive™ reinforced belt spins dry on a steel crank pulley and a hard coated aluminum upper pulley and helps isolate crankshaft harmonics to the valve

COMP Cams HRT Camshaft for Gen III Hemi

Swap your Gen III Hemi’s factory cam for a COMP Cams HRT Camshaft and you’ll boost horsepower without beating up your valvetrain. The hydraulic roller cams have COMP’s Low Shock Technology profiles designed to maximize horsepower, improve stability at higher RPM, and are gentle on the valve springs for longer life. The COMP Cams HRT

Understanding Camshafts – Part 2 (Cam Cores)

There’s a lot of detailed information that comes with camshaft selection, but core size is one of the more important aspects as it dictates several other specifications of the cam itself. Steve explains in this episode. Stay tuned for the final Part 3 video on camshafts. If you missed Part 1, click here.

Understanding Camshafts – Part 1 (Lobe Shape)

The camshaft is to an engine as a conductor is to an orchestra. A lot rides on having the proper camshaft selected for your engine application. In Part 1 of this Steve Tech on camshafts, Steve Morris discusses lobe shape and the importance of choosing the right shape for your expected performance goals. Stay tuned

Camshaft Tech with COMP Cams’ Billy Godbold

We caught up with Billy Godbold to discuss all things camshaft, from common misconceptions to proper camshaft selection to firing order and much more.

COMP Cams HRT Turbo & Supercharger Camshafts for Dodge Gen III HEMI Engines

The Gen III HEMI market is rapidly expanding and the HRT Camshaft Series uses the newest and most advanced lobe designs from COMP Cams in order to produce some of the highest average power and torque increases available.

COMP Cams LST & HRT Performance Camshaft Packages

LST & HRT Performance Camshaft Packages take the guesswork out of choosing the best valvetrain upgrade for your specific engine and desired performance. The Low Shock Technology behind these performance packages features lobe profiles designed to maximize horsepower, while improving stability at higher rpm. These profiles are also easier on the valve springs, enhancing durability and reducing load

Camshaft Art and Science – You Get Out What You Put In

The most misunderstood component of an engine is the camshaft. Selecting a camshaft and understanding its profile and design can be a “black art” as most of what a cam profile controls is invisible – air. Yet, the camshaft has a major impact on engine performance.

COMP Cams FSL Series Camshaft for GM L99 Engines

COMP Cams is introducing the first performance aftermarket camshaft in almost 20 years that is CARB E.O.-pending, offering drop-in convenience, with no valve spring change required, for Gen V (2010-’15) Camaro SS GM L99 engines.

Camshaft Selection

“What camshaft should I use?” How many times have you been asked or heard that question uttered? Why is it so difficult to choose the “correct” camshaft for an engine build? What separates one camshaft design from the other? After all, isn’t it true that a camshaft opens and closes valves? Simple, right? Well let’s

Camshaft Class is Back in Session

A theory prevails in which a cam lobe that opens to maximum lift and closes instantaneously is quintessential for maximum power and torque operation. Two problems exist with this premise. First, it’s highly impractical due to current technology. Second, this theory discounts a fundamental dilemma that air has momentum, and this must be utilized to achieve

Cylinder Head Design & Selection

Choosing the “right” cylinder heads for an engine build can make all the difference in an engine that delivers and one that falls short of its potential. Horsepower, torque and throttle response all depend on how well the cylinder heads, camshaft and induction system work together. Choose the right combination and you’ll build a winner.

Choosing the Correct Camshaft – Bangin’ on the Bumpstick

There are numerous aspects involved in designing an engine combination. Displacement, compression, airflow, etc., and it is the camshaft’s job to ensure that all of these work together properly to achieve optimum performance. That’s why the cam is often referred to as the “brain” of the engine.